Precision farming is one of the developing ways in which agriculture has begun changing its face, embracing datadriven decisions, optimizing inputs, and increasing crop yields. Certain key enablers for such a transformation are based on hydraulic technology. Hydraulic cylinders form a very important part of farm equipment and agricultural machinery in terms of precision, flexibility, and enhanced output of many farming operations. Whether it’s the lift of a plow or the width of a harvester, hydraulic cylinders provide the power to move and position the machinery with high accuracy.

In this blog, we’ll explore the significant role hydraulic cylinders play in precision farming, backed by realworld data, regulations, and technological advancements that showcase how they maximize output and streamline agricultural processes.

Introduction: Hydraulic Cylinders and the Evolution of Precision Farming

From a rather unusual type of farming in the past, precision farming nowadays has grown into mainstream practices in contemporary agriculture. It involves the employment of various advanced technologies such as GPS, remote sensing, and IoT by farmers for accurate monitoring and management of the performance at field levels.

Hydraulic cylinders are at the core of such hightech systems, enabling huge forces to be applied to moving and actuating big farm machinery. As a matter of fact, hydraulic cylinders create opportunities for smooth running and realtime fine adjustments in everything from tractors to combine harvesters. This makes them key parts in the quest for maximal farm productivity while at the same time minimizing operating costs and adverse environmental impacts.

The report entitled Research and Markets indicates that the global agricultural equipment market, in which hydraulic cylinders are significant machinery, will be valued at $250 billion by 2027, while the growth rate is at a CAGR of 4.7%. This reflects an everincreasing demand for farming technologies within advanced levels; indeed, the hydraulic systems are very much important in driving innovation.

By the end of this blog, you will appreciate why investment in highquality hydraulic cylinders, such as those from Shining Hydraulic, will help in improving the performance of your farm machinery to higher levels of efficiency and profitability.

The Mechanics of Hydraulic Cylinders in Agricultural Machinery

What Are Hydraulic Cylinders?

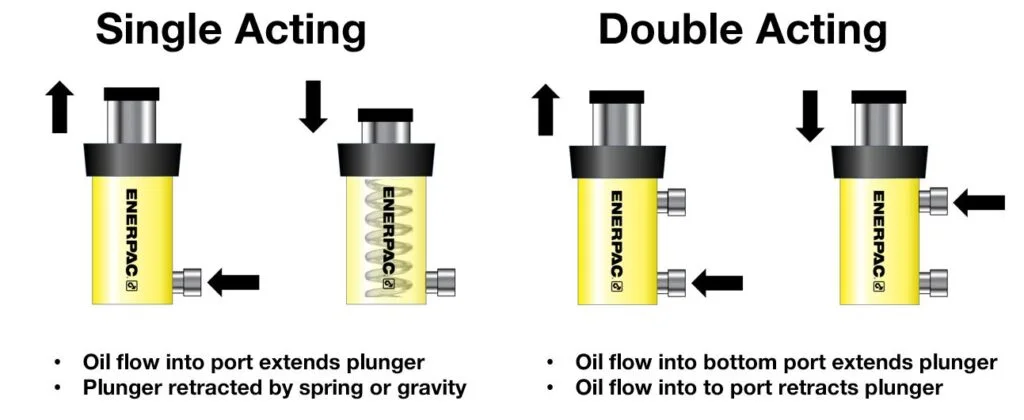

Basically, the hydraulic cylinder is a device of hydraulic energy fluid pressure transfer into mechanical force for farming machinery motions. In simple terms, what that means is that hydraulic cylinders use hydraulic fluids usually oil during the creation of forces with linear motion to provide an accurate control of the equipment in farming.

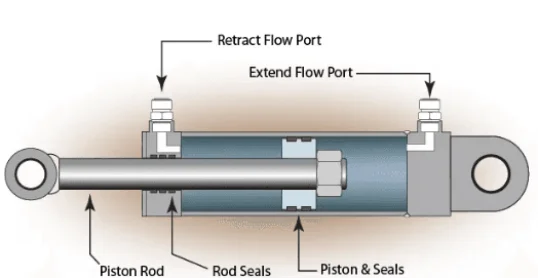

Key components that make up a hydraulic cylinder include:

Cylinder Barrel: It is the major body containing hydraulic fluid and casing for the piston.

Piston: That part which moves along the cylinder barrel and performs the mechanical force.

Rod: The shaft projected from the cylinder that delivers the linear motion to do something.

Seals: They prevent the leakage of the fluid and keep the system safe from impurities.

Hydraulic cylinder application ranges from mere simple to highly complex functions like lifting, steering, and implementation adjustment in agricultural machinery.

How Hydraulic Cylinders Enable Precision in Farming

1. Increasing the Accuracy of Field Operations

Undeniably, on the go adjustments remain the most welcome feature associated with precision farming. Hydraulic cylinders allow millimeter accuracy in changing height, depth, and width of agricultural implements. For example,

Seeders: Hydraulic cylinders regulate seeding units for depth to place seeds at the most appropriate depth for germination. This prevents the wastage of seeds, allowing regular growth of crops.

Plows: Hydraulic cylinders are applied for changing the angle of plowshares. It can provide uniformity in turnover, besides better seedbed preparation.

This will provide very precise control of farm implements that will optimize planting conditions, to which crop yield is directly related. In fact, according to studies from the International Journal of Agricultural Technology, precision planting through advanced hydraulic control systems has been able to increase crop yield up to 30% in some instances.

2. Reducing Fuel Consumption and Improving Efficiency

Agriculture is a very costintensive and operational procedure; hence, this industry needs to be concerned about the judicious use of fuels and energies. Hydraulic systems help in optimizing energy employment, hence making highefficiency power availability right when and where it is needed.

For instance, hydraulic cylinders used in modern agricultural machinery are accompanied by load sensing valves that make the system adjust hydraulic flow according to the load handled, thus avoiding excessive use of energy. This is smart technology that leads toward fuel savings and prolongs machinery life. According to a report by Agriculture and Food Security, precision farming methods can cut fuel consumption by up to 20%, making hydraulic cylinders an important part of the equation.

3. Smart Sensors for Maintenance Cost Reduction

More modern hydraulic cylinders have implemented smart sensors that convey information relating to the real performance of immediate systems. These sensors aid in determining whether there is a drop in pressure, leaks, and wear and tear that can result in more frequency in maintaining such systems if left unattended.

This helps farmers to schedule repairs at an appropriate time and avoid breakdowns during the peak farming seasons. According to the Institute for Precision Agriculture, predictive maintenance can reduce the machinery downtime by 1520% and ultimately increase the productivity of the entire farming operation.

Legal and Regulatory Considerations in Hydraulic Systems for Agriculture

The farm machine design incorporates hydraulic systems not only with regard for technological advancement but also in respect of sensitive areas of consideration concerning safety and protection of the environment. Other varying regulations involving local and international adherence make the obligation of safety and efficacy obligatory to farmers and manufacturing concerns to adhere to.

Every hydraulic component, say hydraulic cylinders, has to pass the strict ISO 9001 and ISO 14001, where the quality management and environmental impacts are concerned, respectively. This provides assurance that hydraulic cylinders would function highly dependably at extreme conditions in agriculture and that their production processes must be in environmentally friendly ways.

In the European Union, hydraulic systems in farm machinery should also be in conformance with the Machinery Directive (2006/42/EC) laying down the essential health and safety requirements for machinery used for farming. Examples of this are specifications on the design of machinery with emergency stop functions and hydraulic cylinder guards to avoid accidents.

Environmental Regulations

Hydraulic systems also need to follow REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in the EU, banning hazardous chemical applications in hydraulic fluid. Regulations guarantee that the environmental impact from the hydraulic operations is minimal very important for a factor which the agricultural sector aims for: being green friendly.

Why Choose Shining Hydraulic for Your Agricultural Machinery?

Shining Hydraulic is one of the reputed hydraulic cylinder manufacturers with its footprints in the agricultural machinery industry. Their hydraulic cylinders are designed to ensure the highest standards of performance, durability, and efficiency, thereby being a perfect fit for precision farming applications.

Here’s why Shining Hydraulic should be your go to supplier for agricultural hydraulic cylinders:

1. Superior Engineering for Precision Farming

Shining Hydraulic supplies precision engineered cylinders for a wide range of applications in agricultural machinery, from round balers, plows, and seeders to grain harvesters; all of them ensure operation at maximum efficiency.

2. Advanced Sealing Systems for Long Life

The hydraulic cylinders at Shining Hydraulic come with the most advanced sealing systems. This reduces leakage and allows this very essential piece of equipment to serve one for a long period. Similarly, highspeed wear resistant seals reduce downtime and operating costs yet another critical determinant in farming operations.

3. Quality and Durability Commitment

Shining Hydraulic pays much attention to strict quality control. Manufactured from highstrength colddrawn steel, the hydraulic cylinders are also fitted with corrosionresistant piston rods for reliability and durability in harsh farming conditions.

4. Customer Centric

Shining Hydraulic is in active communication with customers to understand their needs with the view of offering them customized solutions for machine performance. Its onestop service includes consultation right from the very beginning and involves aftersales support, too, with a view to ensuring that its customers get the best from their machines.

Conclusion: The Future of Precision Farming Depends upon Hydraulic Technology

Hydraulic cylinders will be ever more vital in raising productivity, reducing environmental impact, and making farming operations truly efficient as the agricultural industry becomes increasingly dependent on smart technologies. With Shining Hydraulic at the helm to provide quality and durable hydraulic cylinders for agricultural machinery, farmers can employ advanced hydraulic systems that assure top output with minimum expenses.

This article has proved, based on case studies and statutory regulations, that the use of hydraulic cylinders has a fundamental role in the sector of precision farming as it helps improve output through smart technology combined with strong machinery.