Hydraulic cylinders feature in any modern agricultural equipment used to simplify and boost the output of an agricultural machine. With the rising complexity of farm machinery and pressure for even higher efficiency. On the other hand, making an informed choice will be possible by focusing on those critical factors that affect the performance of hydraulic cylinders.

This article highlights most of the important considerations when selecting hydraulic cylinders for agricultural machinery and gives insights, with products from Shining Hydraulics that have come to be trusted in the agricultural sector.

The Role of Hydraulic Cylinders in Agricultural Equipment

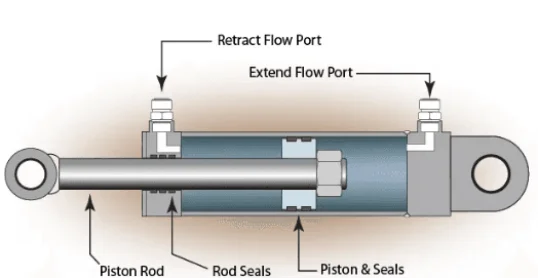

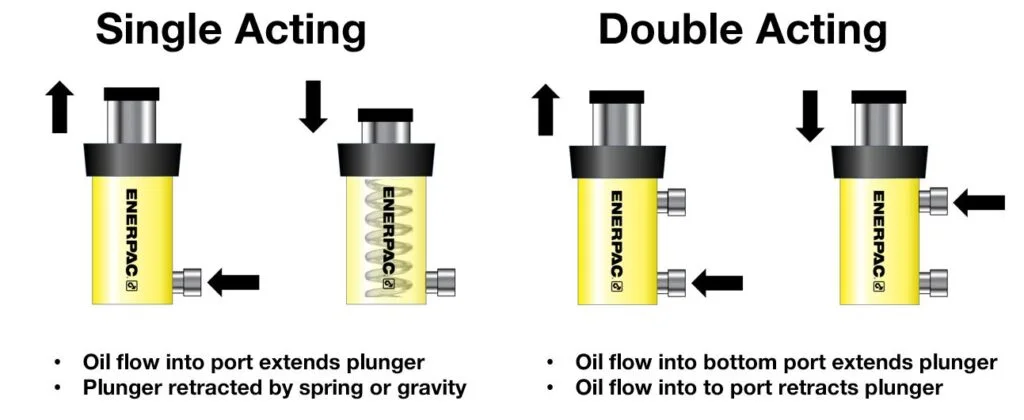

They basically convert hydraulic energy into mechanical force and hence form an important part in machines like tractors, harvesters, mowers, bailers, and plows. Agricultural machinery has been developing to meet modern farming requirements, and the hydraulic systems applied needed not only to be strong but also efficient, accurate, and durable.

Especially in agricultural machinery, hydraulic cylinders are designed to withstand harsh conditions of operation, heavy loads, and extreme temperatures, humidity, and pressures. The performance of the hydraulic cylinders directly impacts the output and safety of agricultural operations.

Parameters of Choice for Hydraulic Cylinders in Agricultural Machinery

1. Operating Pressure and Load Capacity

One of the major determinants in the effectiveness of the machinery that it powers is the operating pressure of the hydraulic cylinder. The hydraulic cylinders can well be engaged to operate under high pressures in the performance of tasks related to the lifting or even pushing of heavy loads, depending on the application. According to the International Journal of Fluid Power, hydraulic systems in agricultural machinery operate between 2000 and 5000 PSI based on the machinery type and the nature of the task.

Of importance is also the load capacity of the cylinder. An appropriate selection of load-carrying capacity for the cylinder will be able to bear the weight of materials to be moved, such as hay bales, soil, and other agricultural products. The load capacity should fall within the scope of tasks that the machine is supposed to perform and assure smooth operation without any risk of damage or malfunction.

Among many, Shining Hydraulics develops hydraulic cylinders of high strength and durability. For example, in its various cylinder designs, like the round balers and mounclers, it has designed them to bear high pressure and hard jobs so that operators will depend on this kind of equipment never to bow down in performance.

2. Sealing and Wear Resistance

The sealing system is the most important factor when selecting hydraulic cylinders. Seals protect the internal components from dirt, moisture, and contaminants, which can lead to expensive repairs and time wasting. Besides, high-quality seals improve longevity, so vital for agricultural equipment that operates under the roughest of conditions.

The agricultural hydraulic cylinder has a better preference for imported sealing brands due to their very high wear resistance capacity and withstanding high-speed operations. Shining Hydraulics hydraulic cylinders incorporate an advanced sealing system designed to assure long service life with reliable performance by reducing the possibility of oil leakage or contamination.

For instance, their hydraulic cylinder for round balers is designed to integrate perfectly with the feeding and compressing actions of the machine. It is further fitted with tough seals that guarantee smooth operation and reduce frequency of maintenance.

3. Impact Reduction Cushioning System

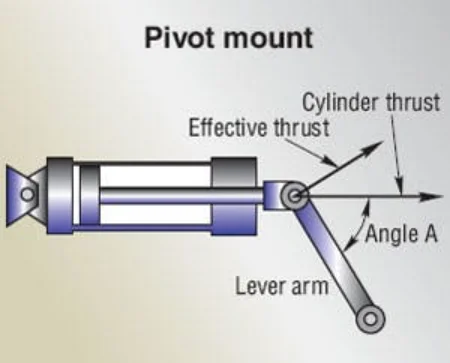

In agricultural machinery, hydraulic cylinders with cushioning systems are also very important when heavy loads are lifted and dropped very frequently. The cushioning mechanism reduces jolting at the end of the stroke while the movement of the cylinder reduces wear on the entire system.

Shining Hydraulics uses special cushioning design within their cylinders; some of their examples include the mounclers and round balers. By reducing the resultant force exerted on the cylinder and other related parts, it enhances the life of machinery and avoids wear and tear on the equipment. The cushioning design reduces the occurrence of component failure and enhances efficiency by absorbing this impact at the end of the stroke.

4. Specific Application Customizations

Every agricultural operation is different, and it is possible to choose hydraulic cylinders that can be customized for particular needs to enhance the general performance of the machinery.

In the case of their hydraulic cylinder for mounclers, Shining Hydraulics tailors the design to meet the specific demands of soil preparation, ensuring that the cylinder performs efficiently for tasks like loosening, crushing, and leveling of the soil. The result is to increase the functionality of the agricultural machinery at a whole new level and solve the problem much more effectively for the farmer.

5. Durability and Anti-Corrosion Features

Agricultural equipment often encounters the worst environment because most times, it exposes machinery to water, chemicals, or dirt that result in the degrading or wear of equipment. Therefore, assurance in building with long-lasting material in hydraulic cylinders, combined with anti-corrosive features, goes a long way in lengthening the service life.

Shining Hydraulics applies high-strength cold-drawn tube technology to the cylinder barrel, making it strong, tough, and wear-resistant. Besides, the piston rods are treated with an advanced electroplating process and pass a salt spray test for as long as 96 hours to guarantee superior corrosion resistance. These features are quite important for agricultural machinery working in humid conditions and among fertilizers and other corrosive elements.

6. Maintenance and After-Sales Service

The finest hydraulic cylinders need constant adjustments and upkeep if they have to endure the time strain. Apart from the manufacture itself, another important criterion would be their after-sales service. Likewise, a sound servicing company offers effective troubleshooting and actual repair service; it also goes to an even higher step-suggesting necessary enhancements towards retaining the high hydraulic system working competence.

Shining Hydraulics stands out in this regard, offering a 12-month warranty on all its hydraulic cylinders, along with comprehensive after-sales support. The company’s customer service team is dedicated to providing guidance on maintenance, ensuring that customers can maximize the performance and longevity of their hydraulic systems.

Conclusion: Choosing the Best Hydraulic Cylinders for Agricultural Machinery

The proper selection of hydraulic cylinders in agricultural machinery is a very important decision, as it will determine the productivity and efficiency, along with the durability, of your machinery.

With advanced engineering, customization options, and a pledge to quality, Shining Hydraulics is one of the largest manufacturers of some of the most reliable hydraulic cylinders for agricultural machinery. Be it for round balers, mounclers, or other agricultural machinery, Shining Hydraulics has a solution to satisfy your every need. Construction that is durable, anti-corrosion, and attention to customer satisfaction-Shining Hydraulics, your partner in the agricultural business.