The hydraulic cylinder has lots of applications starting from construction, mining, and so on. Hydraulic energy, which gets converted into mechanical force by the hydraulic cylinders, is an integral part in a lot of machinery, especially under extreme demands and in heavy-duty sectors. Like every mechanical part, hydraulic cylinders can wear and tear and also malfunction with time. Now, the question arises, whether a hydraulic cylinder can be repaired or not.

Understanding Hydraulic Cylinders Failures

Hydraulic cylinders work under most extreme applications and the least favorable conditions in mining, construction, and agriculture. Because of that fact, such cylinders have to support very high pressure and friction, as well as exposure to various environmental factors that may cause failures in them. Common issues which may require repair include:

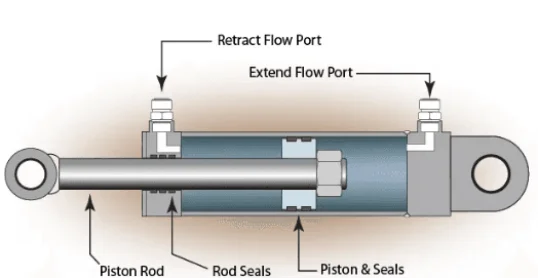

1.Sealing Failures: Seals are what keep hydraulic pressure inside the hydraulic cylinder. Over time, in high temperatures, and contamination, the friction consequences can very easily be one of the major reasons for deterioration that causes leakage and a loss of performance.

2.Piston Rod Failure: The piston rod, while working inside the cylinder, is subjected to very high tension and friction levels. Cracking, bending, or scoring due to corrosion, fatigue, and wear render the piston rod ineffective.

3.Cylinder Barrel Wear: There may be some sort of wear and tear happening inside a hydraulic cylinder barrel due to friction between itself, a piston, as well as a rod. It is the cause for loss of efficiency resulting in the leakage of the oil hence failure of a cylinder.

4.Internal Damage: Internal destruction of the cylinder, seal, and valve by the entry into the hydraulic system by dust, dirt, or metal chips.

5.Corrosion: Out in strong chemicals and seawater, coupled with bad weather, the growth of rust on the surface could be weakening the cylinder structure.

Hydraulic Cylinder Repair Feasibility

Whether hydraulic cylinder repair or its replacement depends largely on the intensity of the damage, cost-effectiveness of the repair to be undertaken, and also the requirement of machinery. A look at some key considerations:

1.Severity of Damage

Hydraulic cylinders, whether repairable or not, depend on whether it’s just a minor problem, like seals having gone bad or a little wear around the piston rod. Sometimes, these seals can be replaced easily, and any light damage on the piston rod may be recovered through grinding or hard chrome plating at times.

2.Cost of Repair vs. Replacement

Considering these aspects, hydraulic cylinder repair may appear as the most affordable alternative; however, minor repairs become the most feasible possibilities only. The bigger repairs tend to become more expensive than just replacing a hydraulic cylinder. More frequent repairs will equally imply an increase in the allowance over the lost work time with an aspect of effectiveness that is not viable for any organization that expects long terms of effectiveness at work.

According to Hydraulic and Pneumatic Systems, Inc., a repair cost for a hydraulic cylinder can be in the range of 30% to 60% of a new one. As said, though repairs may apparently look cheap, businesses do need to have a glance at aspects like frequency, downtime, and long-term reliability.

3.Operational Downtime and Efficiency

For example, mining industries need operations that fully depend on equipment. In other words, the underlying philosophy here is to reduce losses through minimal down times. Repairs might be one solution that would further prolong the life for the cylinder but also tend to cause sudden failures which result in longer down times. Replacement with wrecked cylinders containing durable and long-life replacement assists operations to easily pick up and proceed without losses in pace or efficiency.

4.Skill Availability and Resources

Hydraulic cylinder repair requires expertise and machinery that can dismantle, inspect, and assemble the components. Special machinery, including but not limited to honing machines, welders, and lattes, is made available to reinstate the cylinder to perfect shape. Companies like Shining Hydraulics provide not only the best class of cylinders but also all-rounded support for maintenance and repair so that clients get expert help if any need arises.

Hydraulic Cylinder Replacemen

Though the hydraulic cylinder repairs seem a great option, sometimes it might not be ideal for use, and at that point, it is always advisable to consider a replacement for your hydraulic cylinder. This happens especially when it has been in operation for quite some considerable time and is thus worn out or if the costs outweigh the repair benefits. Here are instances where one should consider replacements over repair:

1.Severe structural damage: All those cases include bending, a crack, deep corrosion of the barrel of a cylinder, such that repair would render neither functional nor safe. Many of these defects require replacement rather than an ability to be merely economically.

2.Repair Cost Too High: When the cost of repair exceeds 50 to 60 percent of the cost of a new cylinder, it is better to replace the hydraulic cylinder for economic reasons.

3.Repeated Failures: When the hydraulic cylinder has been repaired more than once after repeated failure, it will be better in the long run to change it with a new and strong component to minimize lost time and expenditure.

- Parts are Obsolete or Not Available: When the model of the cylinder is too old, and the spare parts that are to be replaced are no longer available, then upgrading to a new cylinder is usually the alternative.

Shining Hydraulics: Your Partner in Hydraulic Cylinder Solutions

Talking about high performance and mining machinery hydraulic cylinders, one really cannot look beyond Shining Hydraulics. Having engaged in the hydraulic industry for more than 30 years, Shining Hydraulics has fabricated cylinders to meet such arduous industries as building, mining, and agriculture, among others.

Why Choose Shining Hydraulics for Mining Machinery Cylinders?

The company designs and manufactures independent and tailored hydraulic solutions for each and every special need of its customers. Hydraulic cylinders boast long service life, precision engineering, and dependability in mining machinery. These are some distinguishing features for which Shining Hydraulics comes so highly recommended:

- High-Strength Material:High-strength cold-drawn material for cylinder barrels and 45-hardened steel for piston rods ensure high performance even under extremely adverse conditions.

- Advanced Sealing Technology:Shining Hydraulics uses the imported sealing brands NOK and Hallite, improving reliability and life for their hydraulic cylinders.

- Customization:Whether you need a cylinder operating in an extremely high or low temperature or any other special design, Shining Hydraulics provides a solution tailored just for your specific needs.It can provide a one-stop service to ensure that your equipment runs without the slightest problem-from initial consultation, product development to after-sales support.

- Innovative Technology:Equipped with a powerful R&D team, Shining Hydraulics keeps working in developing new technologies, improving hydraulic cylinders for mining machinery, and so on.

Conclusion

Hydraulic cylinders are usually repairable, but of course, there is a question of the extent of the damage and cost, bearing in mind the value of uptime for the equipment. Small-natured issues in large quantities get fixed; in other, more serious types of damages, replacements probably would occur. Applying good-quality hydraulic cylinders from organizations like Shining Hydraulics will definitely provide the best results from one’s mining equipment.

The selection of reliable, durable, and customized hydraulic cylinders would thus be a strategic business decision for companies in the mining sector, ensuring minimal operational downtime while reducing maintenance costs and enhancing productivity. Take it from Shining Hydraulics-the best hydraulic cylinders for modern machinery in mining.