Hydraulic systems are an everyday phenomenon in the construction, agricultural, automotive, and aerial work platform industries. Hydraulic systems function due to the frictionless motion of hydraulic cylinders to transport equipment and accomplish the work. Hydraulic systems are susceptible to leaks, though, that can reduce productivity, induce unscheduled downtime, and even be a safety risk. For hydraulic leaks to occur as and when they occur is not just for your machine to operate but also for workers not to get hurt and further damage not to happen.

What Do You Do When You First Notice a Hydraulic Leak

How Do You Find Where the Leak Is

Where it is leaking must first be ascertained in attempting to fix a hydraulic leak. Leaks will generally present themselves as dripping, spraying, or puddling around the hydraulic cylinder or apparatus component. Visual inspection is still the best way of looking for such a symptom. Systematically check areas like hoses, fittings, seals, valves, and the hydraulic cylinder itself for defective parts. Inspect any concealed wear, rust, or crack that will most likely show you where the leak initially occurred. Where pinch spots are worn areas, attempt to look in with flashlight and mirror.

How Do You Determine the Size of the Leak?

Once you have identified the leak source, you will need to size it. Minor leaks and minor drips are repaired by maintenance or routine repair. Gigantic leaks or dangerous ones to workers and operators need to be repaired promptly. Based on the leak size and based on the type of leak, you will need to replace hydraulic cylinders, hoses, or seals.

Why Is It Necessary to Shut Down the Hydraulic System When Fixing a Leak?

What Are System Shutdown Safety Procedures?

Always completely shut down the hydraulic system before repairing in an effort not to experience any accident or injury. Use manufacturer guidelines and standard safety procedures. This is done through de-energizing supply power lines, bleeding hydraulic pressure, and utilizing lockout/tagout procedures so that the system cannot be accidentally energized for repair. System shutdown is carried out for safety to the person making the repair and to prevent the integrity of the system being compromised by means of repair. How Do You Properly Repair a Hydraulic Leak?

Why You Should Clean the Area First Before Repairing

The area that is leaking should be cleaned before it is repaired. Dirt, grime, or residual oil will clog the repair and even worsen the damage. Wipe the leak area with a solvent or a degreaser and a lint-free paper towel or rag. This is so that there is no contaminant that will find its way into the system and cause problems later.

How do you replace gaskets, fittings, and seals?

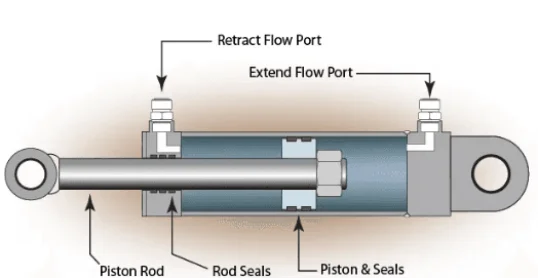

Damaged, worn out seals, gaskets, or fittings are responsible for the majority of hydraulic leaks. Once you have located a leak in one of these types of units, you will be compelled to unscrew the bolts of the affected unit without any further damage to any of its parts. To do this, you will need some specialized tools, such as seal picks or pry bars, to pry the loose leaking gasket or seal. Inspect the sealing surface for damage or wear and replace the unit with a new replacement adequate to your system. Seat and position the new seal or gasket correctly in an effort to prevent future leaks. Inspect all connections and fittings throughout the system also for looseness. Loose fittings also create friction and must be tightened with a wrench or socket but not so tight that you strip the parts.

How Do You Fix or Replace Damaged Hoses and Tubing?

If the leakage is due to a ruptured hose, pipe, or tube, they can be repaired or replaced. Check damage for puncture, cut, or abrasion. Little damage can be sealed by employing a repair kit or clamp, but extensive damage will require a new assembly of the hose. Replacing the hose will ensure maximum long-term performance and future prevention of leakage.

How Do You Test and Prevent Future Hydraulic Leaks?

What Tests Are Done Following Repairs?

After sealing the leak, the system is then to be tested for the operation of a normal system and whether or not the repair has worked. Put back all the fittings, lines, and components first. Then, increase hydraulic pressure gradually and monitor for pressure loss or leaks. Observe the pressures on a pressure gauge and notice any variation that is an indication of incipient faults.

Upon pressure testing, perform a system functional test. Cycle the actuators, valves, and controls and verify that they are in fine working order. Check for unusual vibration, noise, or excessive heat, all symptoms of defects to be remedied. This diligent procedure is designed to test the system health and ensure it is running at optimum levels.

What Preventive Measures Should Be Implemented So That One Never Has Leaks in the Future?

To avoid hydraulic leaks in the future to the maximum extent possible, it is very essential that a preventive maintenance program be implemented. The hydraulic system should be inspected regularly so that the wear and tear, corrosion, or whatever else will create the leaks in the future can be detected in advance. Make sure replacements of parts such as seals, filters, and oil are carried out according to the manufacturer’s recommendation. Accurate records of all the maintenance activities are required in keeping your hydraulic system record and avoiding any potential complications in the future.

How Can Shining Hydraulics Assist You with Quality Hydraulic Cylinders?

Why Shining Hydraulics?

For high-quality hydraulic cylinders, you have arrived on the right site at Shining Hydraulics. Shining Hydraulics is a trusted company with a track record of more than 20 years of hydraulic cylinder manufacturing and designing to supplied specifications such as aerial lifts, agricultural machinery, and construction vehicles. Paying emphasis to dependability, precision, and quality, you are sure to get the product in your accurate specification.

Shining Hydraulics believes in manufacturing world-class, high-performance products by a rigorous quality control process so that every hydraulic cylinder exceeds industry standards. With its customer satisfaction philosophy, Shining Hydraulics provides technical solutions, quick service, and technical support to enable your business growth. With special designs to over-the-shelf hydraulic products, Shining Hydraulics is your promise of efficiency and reliability for your machinery.