Hydraulic cylinders-whether it concerns the building site, agriculture, mining, or any other heavy-duty industry-knowing how long these components of any machine should last is crucial to maintaining operational efficiency while reducing downtime and optimizing costs. But, like many industrial products, the lifespan of a hydraulic cylinder depends on a variety of factors. Below, we present the basic key elements of factors that have effects on the life span, accompanied by insights into how to take maximum service from hydraulic cylinders, along with information about what one leading company is doing: how Shining Hydraulics is changing faces through advanced technologies in the world hydraulic cylinder solutions with long lives and performance.

The Basics: What Affects Hydraulic Cylinder Lifespan?

A hydraulic cylinder’s service life is not a single-point figure. Typically, a hydraulic cylinder that has been well-maintained could last anywhere between 5,000 to 10,000 hours of operating time. This can be shortened or extended due to several factors. Understanding these factors is essential in making the right investment decisions and selecting the best hydraulic cylinder supplier.

1.Design and Quality of Materials

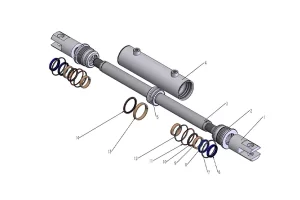

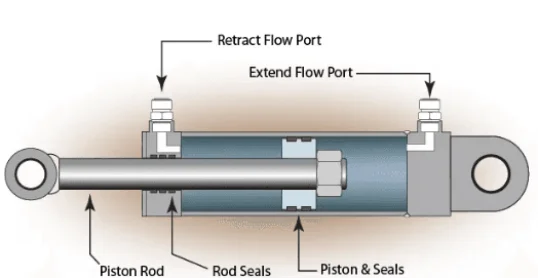

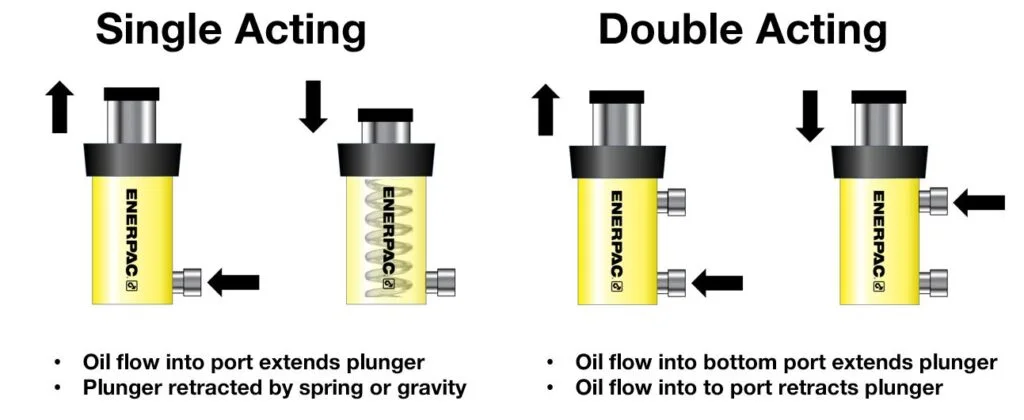

Materials used during manufacture are one of the most critical factors in determining the life of hydraulic cylinders. For example, hydraulic cylinders manufactured by Shining Hydraulics apply high-strength cold-drawn material for cylinder barrels, ensuring strength in structure and high-pressure resistance. Advanced electroplating methods, such as Ni/Cr electroplating and QPQ for piston rods, enhance corrosion and wear resistance, two critical factors in extending the service life of the cylinder.

Shining Hydraulics company adopts high-quality, imported sealing brands, such as NOK, so that the sealing system can resist high-speed wear and increase the service life of the cylinder further.

2.Operating Environment and Conditions

Hydraulic cylinders are designed to work within a particular operating condition, and exceeding this condition can reduce the life expectancy by a huge margin. For example, cylinders that are exposed to extreme temperatures-for example, from -25°C to +120°C-might wear out faster if they were not designed to operate within those parameters. Temperature range customization, such as provided by Shining Hydraulics, ensures hydraulic cylinders fit for the job, reducing the possibility of premature failure.

3.Maintenance Practices

The normal life of hydraulic cylinders is mainly enhanced by undertaking good maintenance practices. Basic visual inspections in search of leaks, replacement of the seals, or any wear in the head of the cylinder or corrosion around it can more than double the life of cylinders. If they are neglected, efficiency drops along with damage to seals and leads to costly replacement.

Shining Hydraulics has a very strong building of its reputation via reliable service and support, wherein it rightly focuses on customer-oriented solutions, including tips on how to properly maintain cylinders for their longer service life.

Role of Advanced Engineering and Innovation

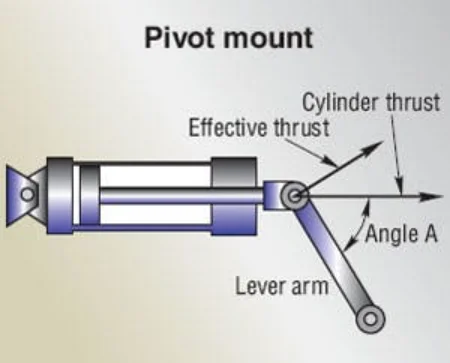

Innovation with advanced engineering plays a core role in the manufacture of hydraulic cylinders with strength and efficiency at Shining Hydraulics. Their team, featuring experts in hydraulic technology and industrial engineering, guarantees design for every cylinder to meet the highest standards possible. With advanced features such as forged connection parts integrated into the design and professional cushion designs that minimize impact during operation, the cylinders from Shining Hydraulics go an extra mile in their performance for the life of operation.

In addition to maintaining clean production, the lean manufacturing processes at the company ensure that each unit is of quality and consistent with its standards. Attention to these details in design, materials used, and manufacturing processes assures hydraulic cylinders coming out from Shining Hydraulics to have a very long life.

The Usual Operational Life of Hydraulic Cylinders

As already said, service life normally stands in the region of 5,000 to 10,000 hours; that could be adjusted in line with many other factors-for instance, in those cases where the cylinder would go through heavy-duty work cycles, it will obviously wear out much faster owing to constant loading and unloading stresses that can be applied, say, in construction machinery.

- Light-duty Applications: The cylinder could last longer, up to 10,000 hours with good maintenance, in those applications where high load-bearing capacity is not so demanding, like in aerial work platforms or port forklifts.

- Heavy Application: In industrial hydraulic cylinders such as in building machinery or heavy machinery mining where the working situation is tougher may last for roughly 5,000 hours before they are critically damaged, for which no corrective measure may again work.

The Importance of Proper Cylinder Customization

Customization is one of the major reasons hydraulic cylinders will last longer. Each company requires hydraulic cylinders in an industry that is designed for particular operational requirements. Shining Hydraulics is good at this, offering customized hydraulic solutions based on required temperature tolerance, load capacity, and operating environment. Their hydraulic cylinders can be designed with particular coatings, materials, and configurations to best suit your machinery.

For example, Shining Hydraulics treats the cylinders with special electroplating techniques that make the cylinders resistant not only to wear but also to corrosion. The latter feature is critical for machinery operating outdoors or in contact with water or harsh chemicals.

Real-World Example: How Shining Hydraulics Enhances Cylinder Durability

Consider hydraulic cylinders used in mining machinery. These applications may be under very high pressure on the cylinders, and operating conditions could also be quite harsh, with exposure to dust, dirt, and chemicals. Advanced sealing systems in Shining Hydraulics cylinders protect against the ingression of debris that normally causes early wear. Besides, the cylinders are designed to resist very extreme pressure cycles for a long life, even in difficult conditions.

Why Choose Shining Hydraulics for Your Hydraulic Cylinders?

With the increasing demand for high-performance hydraulic cylinders, it is vital to get in touch with a supplier that addresses critical needs of durability, quality, and innovation. Founded in 2021, Shining Hydraulics quickly rose to become among the frontrunners in the hydraulic engineering industry-securely planting solutions for construction, agriculture, mining, and much more.

Their hydraulic cylinders are highly designed based on quality and durability, with a set of features that demonstrate the leading position: high-strength material for durability, advanced electroplating methods like Ni/Cr and QPQ against corrosion, imported sealing systems for long-time performance, and custom designs regarding temperature range, load, and specific machinery requirements.

A customer-oriented approach that ensures product satisfaction, assured of a reliable after-sales service experience.

By choosing Shining Hydraulics, you are choosing a partner proven to supply top-class hydraulic products for longevity in service.

Conclusion: Future-Proof Your Business with Shining Hydraulics

When it comes down to hydraulic cylinders, there really is no substitute for class and precision. A correctly selected supplier combined with good maintenance practices will go a long way in extending the life of hydraulic systems and bringing out their optimum performance. For unparalleled expertise, high-quality products, and customer-centric approach, Shining Hydraulics has positioned itself as the foremost choice for companies wanting to future-proof their operations.