Hydraulic cylinders form a part of each piece of equipment, be it industrial equipment or construction equipment. Hydraulic cylinders are always under tension and exposed to abusive conditions during and through this and this does place them under wear and tear. Taking measures by measurement and inspection on a regular basis with utmost precision is demanded so that they work efficiently, get damaged less frequently, and their longevity increases.

Why Precision is Needed when Hydraulic Cylinder Wear is Taken

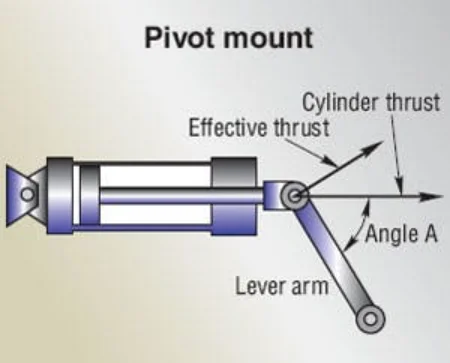

Hydraulic cylinder measurement accuracy is crucial. Small tolerance errors can yield collosal issues like inefficiencies, leakages, or collapse. Hydraulic cylinders are based on motion of exact quantities of fluid over exact quantities of space. Variation in dimensions, variation in alignment, or wear and tear in parts will make the system incapable of functioning, leading to increased friction, increased number of leaks, and reduced component lifespan. All can be avoided if you measure properly and can increase operation life of the cylinder and the parts.

Tools You Must Use to Measure Properly

Appropriate tools are needed when you require precise measurement of hydraulic cylinder. The following are the tools that you must use:

- Measuring Tapes and Rulers:Simple yet unavoidable measurements to get an exact measure of the whole length of the cylinder. Flexible measuring tape is particularly useful in confined areas, and metric or imperial measurement is handy.

- Calipers and Micrometers:They provide greater accuracy in measuring thickness and diameters. Calipers are found in vernier, dial, or digital forms, whereas micrometers provide very accurate and minute readings.

- Cylinder Measuring Jigs: These specialized jigs to position the cylinder parts to measure accurately and exactly with least movement error.

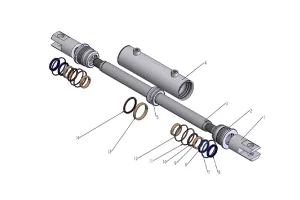

Basic Components to Measure for Wear and Tear

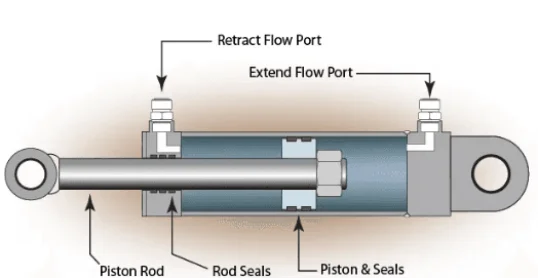

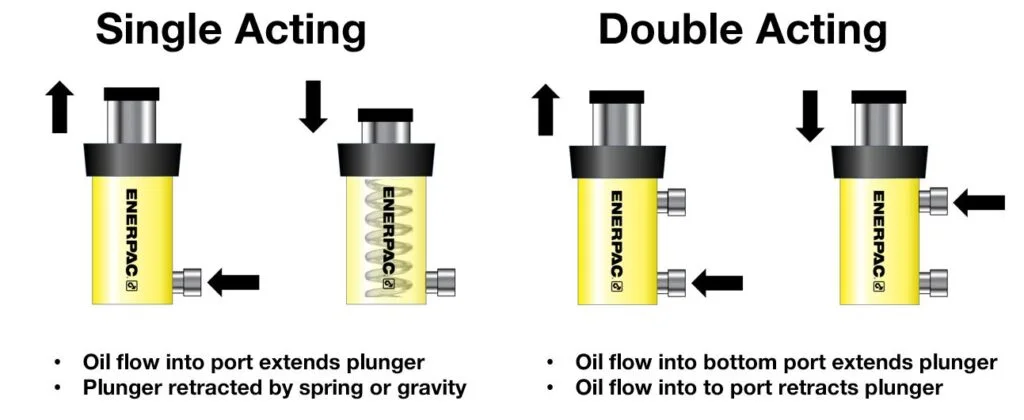

To accurately measure hydraulic cylinder wear and tear, you will have to address some extremely important factors. They are cylinder bore diameter, stroke length, rod diameter, and end caps.

Cylinder Bore Diameter Measurement

The internal diameter of the bore within the cylinder has a direct effect on hydraulic cylinder force. This is how you should do it correctly:

- Take Safety Precautions: Drain hydraulic system and shut off power sources.

- Clean the Bore:Remove impurities within the cylinder bore so that you measure accurately.

- Measure with Calipers:Place the calipers across the bore of the cylinder in right angle and note the internal diameter.

- Multiple Measurements:Measure the bore at various points along the length to verify any inconsistency or irregularity.

Check using a Micrometer: Read the calipers’ reading by using a micrometer for greater precision.

Measuring Cylinder Stroke Length

Stroke length governs piston rod travel and force applied by the hydraulic cylinder. To accurately measure the stroke length, proceed as follows:

- Mount the Cylinder: Position the cylinder upon a firm base and have it in horizontal position.

- Retract the Rod: Hydraulically or manually retract the piston rod to full retraction.

- Mark the Starting Point: Mark the rod end temporarily with a non-permanent marker.

- Extend the Rod: Extend the piston rod to full extension.

- Measure the Stroke:Measure between the mark and the extended rod end with a tape measure.

- Document:Document your measurements for future reference.

Measuring Rod Diameter

The rod diameter will define the cylinder’s push and pull capability. Here is how to measure it precisely:

- Ensure Safety: Depressurize the system and drain the hydraulic power source.

- Clean the Rod: Clean the piston rod of any hydraulic fluid or dirt.

- Use Calipers:Measure the rod diameter at various locations using the caliper, keeping it perpendicular to the rod surface.

- Cross-Check with Micrometers: Measure more precisely using a micrometer.

- Document the Results:Record the sizes for future reference.

Measuring End Cap Sizes

- Ensure Safety:Depressurize and isolate the cylinder.

- Remove the End Cap:Remove the end cap from the cylinder assembly.

- Measure Outer Diameter (OD):Measure the outer widest using a micrometer or caliper.

- Measure Inner Diameter (ID):If applicable, measure inner diameter in hopes of discovering proper replacement seals or parts.

- Measure Thickness: Use your caliper depth gauge to obtain a reading on end cap thickness.

- Check Mounting Points: Record mounted features that are fixed, i.e., flanges or threads.

- Record the Findings:Record all measurements and, where possible, draw them out to understand them..

The Importance of Measuring

Documentation should be precise to capture wear, maintain repair scheduling, and determine if replacement parts will be to original specifications. To document precisely, adhere to the following guidelines:

- Utilize a Special Log:Set aside a special notebook or computer program for hydraulic cylinder measurement. It provides consistency and reference to previous data.

- Plot Diagrams: Putting pieces in drawings with measurements makes it easier to understand and measurement will come in handy later.

- Timestamp Your Entries: Always date and time stamp to track the wear pattern over time.

- Include Anomalies:Identify any anomalies, e.g., uneven wear or damage.

- Compare with Specifications: Compare your measurements periodically to manufacturer’s specs for possible issues.

- Store Records Safely:Store paper and electronic records safely for easy access and future reference.

Mistakes to Avoid When Measuring Hydraulic Cylinders

Accurate measurements are crucial, but there are certain mistakes that undo your work. Avoid the following errors:

- Not Cleaning the Parts:Grease, grime, and other impurities can distort measurements and ruin your equipment. Clean parts before measuring.

- Overlooking Tool Calibration: Your non-calibrated tools can give you erroneous readings. Calibrate your tools regularly to maintain them as accurate as possible and avoid errors.

Join Shining Hydraulics for Quality Cylinders and Support

We at Shining Hydraulics understand the value of hydraulic cylinders for your equipment. With over 20 years of experience, we offer high-quality hydraulic products that are designed to fit your specifications.

Why Shining Hydraulics?

- Tough Quality Control: Each of our hydraulic cylinders is tested rigorously for utmost quality from raw material to finishing inspection.

- Tailor-Made Solutions:We work with you to meet your own unique needs so that your hydraulic cylinders are built to your specifications on your drawings.·

- Technical Expertise: Technical advice and consultancy from our experienced technical experts help and advise you.

Get in touch with Shining Hydraulics today to learn more about hydraulic cylinders and how we can modernize your machines.

Conclusion

Accurate and regular measurement of hydraulic cylinders is what enables optimal working efficiency, security, and longevity. Proper tools, proper technique, and no error mean you getting the most out of your hydraulic cylinders, thereby avoiding failure opportunities and guaranteeing smooth and efficient operation for a lifetime.