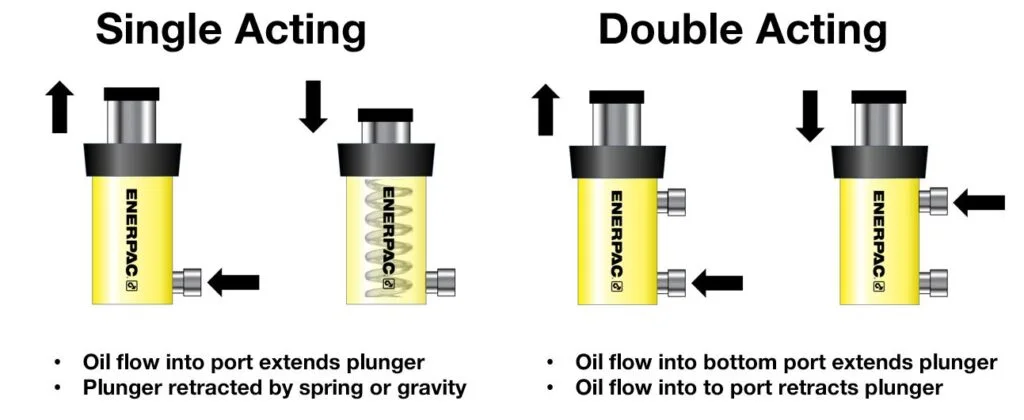

Hydraulic cylinders are essential for powering machinery in different industries like construction and agriculture by providing the required force to move heavy loads efficiently over an extended period of time.

Diagnosing Hydraulic Cylinder Issues

Before beginning the repair process, thoroughly inspect the problem at hand to pinpoint it accurately. It is crucial to recognize the signs of a cylinder malfunction, as it can save both time and money in the future. Here are some common signals that indicate your cylinder may need attention:

1.Fluid Leaks: Look for any signs of leaks around the cylinder body or connections that could point to escaping and hint at possible problems with the seals or other parts.

2.Loss of Pressure: If you’re experiencing issues with your system struggling to lift or move objects or if you’re observing a drop in power performance levels, it might indicate that the cylinder is starting to fail.

3.Erratic Movement:There might be an issue with the cylinders if they exhibit inconsistent movement patterns, like jerking motions; this could indicate potential internal wear or damage has occurred.

4.Excessive Noise: If you notice loud grinding or squealing sounds when the engine is running smoothly, it could indicate a problem with the components of the cylinder.

Additional issues to consider include tools losing pressure faster than anticipated or the increasing difficulty of lifting objects efficiently. and observing for any unexpected leakage.

Essential Tools and Materials for Hydraulic Cylinder Repair

Ensuring you have all the necessary tools and materials is crucial to repairing a hydraulic cylinder; therefore, I’ve provided a comprehensive list of everything you’ll need.

Seal Kit: A package containing seals, O rings, and essential components for replacement needs.

Hydraulic Oil: Make sure to use the hydraulic fluid for your system.

Wrench/Spanner:You would typically use a wrench or spanner to either tighten or loosen components.

Allen Wrenches: Allen wrenches are tools for working with set screws or fasteners with Allen heads.

Rubber Mallet & Punch:A rubber mallet and punch can be employed to gently tap or extract components without causing damage.

Torque Wrench:When tightening nuts and bolts, a torque wrench is employed to meet the requirements outlined by the manufacturer.

Cleaners and Emery Cloth:Cleaners and sandpaper are utilized for cleaning and polishing parts and components.

Be sure you’ve got all the tools to make your repair work more efficient and effective.

Step-by-Step Guide to Repairing Your Hydraulic Cylinder

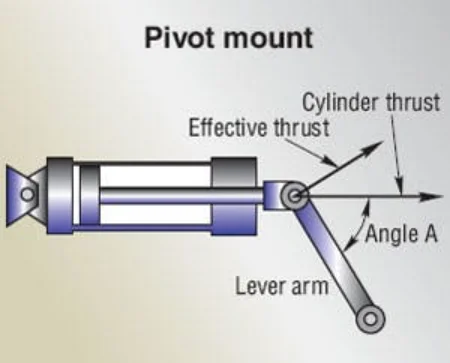

Repairing a cylinder requires precision and careful focus on details as it involves steps that vary depending on the type of cylinder being worked on while maintaining a consistent overall approach throughout the process. Here is a step-by-step guide to assist you in completing the task:

1. Disassembly: Safely Opening the Cylinder

Make sure to have all safety precautions in position to beginning the process of taking things apart.

Release Pressure

Make sure to release all the pressure from the cylinder before beginning any repairs by moving the control lever to fully relieve any remaining pressure.

Disconnect Hydraulic Lines

Remember to disconnect the hoses from the cylinder and seal off the ports to avoid any dirt or debris getting in.

Secure the Cylinder

Make sure to position the cylinder in a vise or another reliable tool to prevent any movement when disassembling it.

Remove the Piston Rod

Make sure to use the tool to remove the pin from the end of the rod, as it may require tools according to the manufacturer’s guidelines.

2. Repairing and Replacing Worn Parts

After examining the cylinder parts to check for any problems or signs of damage and deterioration, it’s time to determine the specific components that require replacement with new ones.

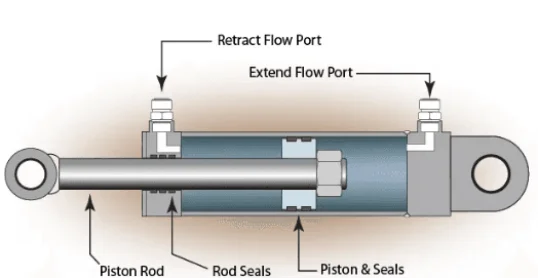

Inspect All Components

Make sure to inspect all components of the cylinder including the rod seals, piston, and cylinder bore. Check for any signs of wear and tear, scratches, or significant damage. If you discover any damage on the piston or cylinder, think about replacing them.

Replace Seals and O-Rings

Make sure you use the seal kit to change any seals and O rings that require replacement, and be sure to confirm that all the new seals are fitted correctly to avoid any leaks.

Hone the Cylinder Bore

If you see any scratches or damage on the inside of the engine block or cylinder head surface while checking during maintenance and inspection tasks, you will need to do honing to make sure the surface is smooth again. One way to do this is by using a tool called a cylinder honing tool.

Repair or Replace the Piston Rod

If the metal rod, inside the cylinder is bent or has any signs of rust or scratches on it that may affect its performance and smooth operation, it’s best to replace it with an one to keep the cylinder running smoothly and efficiently.

Refurbish Piston Heads

Check the piston head carefully for any indications of damage; if it seems worn or compromised in any manner, think about swapping it out with a new one to guarantee the cylinder functions at its best performance level.

3. Reassembly: Putting the Cylinder Back Together

Once you have swapped out the parts with ones during the cylinder assembly, it’s time to reassemble everything together.

Lubricate Components

Before reassembling everything, more ensure to generously apply clean hydraulic oil on all seals, O rings, and moving parts. This particular step is very important to guarantee operation and long term durability.

Reassemble the Piston Rod and Piston

Be sure to apply thread lock adhesive when securing the piston rod bolt to ensure it remains securely in place.

Reinsert the Gland

Place the gland back into the cylinder without using any thread locking substances on its threads to prevent it from getting stuck.

Reattach Hydraulic Lines

Once you have assembled the cylinder and reconnected the lines, take a close look to check for any potential leaks around the newly replaced seals.

4. Testing and Adjustment: Final Checks for Optimal Performance

After reassembling the cylinder, be sure to give it a test run to ensure everything is working as it should.

Pressure Test

Reconnect the cylinder to the setup. Gently exert pressure on it while carefully inspecting for any signs of leakage around the seals or other components.

Operational Test

Turn the cylinder around in all directions. Check how smoothly and quickly it moves to assess how well it works before using it again.

Adjustments

Make sure to adjust the pressure and flow accordingly to ensure that the cylinder is functioning at its level of performance, which may involve fine tuning the system for maximum efficiency.

Best Practices for Hydraulic Cylinder Disassembly

One crucial part of the repair process is to inspect and evaluate the components while giving special attention to…

If you observe any marks or deformations on the surface of the piston rod, it may be advisable to think about replacing it.

If the seals become worn out or damaged over time, it’s crucial to replace them to avoid any leaks down the line.

Why Choose Shining Hydraulics?

When it comes to notch cylinders that you can count on for your requirements, Shining Hydraulics stands as a trusted option in the field of hydraulic solutions. Established in 2021, this company draws upon than 20 years of engineering experience and is committed to providing high quality products and services that ensure optimal performance.

Final Thoughts

Repairin’ a cylinder on your own could help you save some money of buying a brand new one outright! Simply follow the guidelines provided in this manual and ensure you gather the tools and parts for the task – this will help you get your cylinder back in working order smoothly and ensure its longevity.