Overview of Hydraulic Cylinders in Agriculture

Understanding Hydraulic Cylinders and Their Functionality

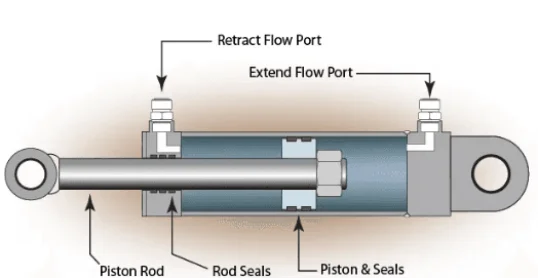

Hydraulic cylinders are key parts of today’s farming tools. They work using hydraulics, which relies on pressurized liquid to create straight-line movement and strength. These units turn liquid energy into mechanical power. This allows heavy objects to be raised, shifted, or managed accurately. A hydraulic cylinder includes a barrel, piston rod, seals, and a fluid entry point. The liquid under pressure pushes the piston inside the barrel. This makes the rod stretch out or pull back.

In farming, hydraulic setups are vital. They power machines needing strong force but must stay small and effective. A small hydraulic cylinder is especially useful. It provides great performance in tight spaces. Shining Hydraulic produces various professional types of agricultural hydraulic presses, suitable for all kinds of agriculturalwork.

Key Features of Small Hydraulic Cylinders for Agricultural Use

Small hydraulic cylinders are built with traits that suit farming jobs. They are small but tough. They can handle rough conditions like dirt, water, and extreme heat or cold. These units often use materials that resist rust, such as stainless steel or coated surfaces. This boosts their lifespan.

Also, a small hydraulic cylinder gives exact control over motion. This precision matters for tasks like planting seeds or setting the angle of tools like plows. Many types offer adjustable stroke lengths and pressure levels. These fit various farming needs. Their dependability and simple upkeep make them a top pick for farmers aiming to improve work efficiency.

Common Applications of Hydraulic Cylinders in Farming Equipment

Role of Hydraulic Cylinders in Tractors

Tractors are central to farm work. Hydraulic cylinders boost their abilities. These units are used in attachments like loaders, backhoes, and three-point hitches. For example, a front-end loader uses hydraulic cylinders to lift and tilt its bucket smoothly.

The steering system in tractors also uses hydraulic power. It ensures easy and smooth handling. By turning liquid energy into motion, a small hydraulic cylinder lets tractors tackle heavy tasks. This reduces strain on the driver.

Integration of Hydraulic Systems in Harvesting Machinery

Harvesting tools like combines and balers rely heavily on hydraulic systems. In combines, hydraulic cylinders adjust the height of cutting platforms. They also control grain unloading arms. This flexibility helps farmers adapt to different crop conditions quickly.

Balers use hydraulics to press hay or straw into tight bales efficiently. The compact size of a small hydraulic cylinder fits these machines well. Space is often limited in them. Their ability to provide steady force creates uniform bales. This improves storage and transport ease.

Use in Plowing and Seeding Equipment

Plowing and seeding tools gain much from small hydraulic cylinders. In plows, these units set the depth and angle of blades. This suits various soil types and conditions. Such flexibility improves soil prep quality. It also cuts fuel use.

Seeding machines use hydraulics for accurate seed placement. Seeds are placed at set depths and spacing. This boosts crop growth and reduces seed waste. A small hydraulic cylinder allows smooth adjustments during work. It ensures top performance across different lands.

Benefits of Using Hydraulic Cylinders in Agriculture

Efficiency and Precision in Farming Operations

Hydraulic systems bring great efficiency to farming. They automate tasks that would take much manual work or bigger machines. A small hydraulic cylinder offers a high power-to-size ratio. This allows compact equipment without losing function.

Precision is another big plus. Hydraulics ensure accurate task completion. This includes controlling water flow in irrigation or tweaking machine settings on the go. Such control leads to better resource use and higher output.

Durability and Reliability of Small Hydraulic Cylinders

Farm settings can be tough on gear. Dust, mud, water, and temperature changes challenge equipment. A small hydraulic cylinder is built to endure these. It uses strong materials and advanced seals to stop leaks.

Their reliability cuts downtime from breakdowns. This is key during busy farming seasons. Time matters then. Regular hydraulic cylinders repair keeps them running long. This adds to their cost savings.

Yantai Shining Hydraulic Technology Co., Ltd. provides custom solutions for special farming needs.

Maintenance and Repair of Hydraulic Cylinders in Agriculture

Importance of Regular Maintenance for Optimal Performance

The dependability of hydraulic cylinders in farm tools relies on steady care. These parts work under high pressure. They face harsh conditions like dirt, water, and temperature shifts. Skipping care can lower efficiency. It increases downtime and leads to costly fixes.

Regular checks are vital. They spot early wear signs. Look for leaks, worn seals, or rusted parts. This keeps the system working well. Lubrication reduces friction between moving pieces. It lowers wear and extends life. Cleaning outer surfaces stops debris from entering. Debris can harm performance.

Hydraulic cylinders repair is needed when problems appear. For instance, swapping out old seals or fixing a bent rod can restore function. This avoids replacing the whole unit. Proactive care boosts equipment performance. It also saves money by preventing big failures during key farm tasks.

Identifying Common Issues Requiring Hydraulic Cylinder Repair

Several issues often call for hydraulic cylinders repair in farm tools. Leaks are common. They often come from worn seals or a damaged barrel. Leaks lower system pressure. This causes inefficiency and may pollute the fluid.

Rod bending or scratching is another problem. It can happen from heavy loads or poor alignment. A bent rod affects smooth motion. Scratches can harm seals and cause leaks. Rust is a concern too. It’s common in wet areas or near fertilizers.

Internal wear is harder to see but serious. Over time, pistons and bearings wear out from constant high-pressure use. This can weaken force output or cause uneven motion.

Fixing these issues quickly through hydraulic cylinders repair keeps farm gear running. Farmers should use skilled technicians. They know hydraulic systems well. This ensures reliable repairs.

The Future of Hydraulic Cylinder Technology in Agriculture

Innovations Driving the Development of Advanced Hydraulic Systems

New advances in hydraulic tech are changing its use in farming. One big step is adding smart sensors to hydraulic cylinders. These track pressure, temperature, and position live. They provide data for predictive care. Spotting issues early cuts downtime. It boosts efficiency.

Electro-hydraulic systems are growing too. They mix electronic controls with standard hydraulics. This gives better precision and automation. For example, they allow variable speed control. They also sense loads. This optimizes power for specific tasks.

Compact designs are also rising. A small hydraulic cylinder delivers high output in tight spaces. This allows more flexible farm machines. They work well across varied lands.

Manufacturers explore green materials too. Energy-saving designs align with sustainability goals. Lightweight alloys and eco-friendly fluids cut environmental harm. They keep durability and performance.

Potential Impact on Sustainable Agricultural Practices

Hydraulic cylinder tech advances aid sustainable farming. Smart systems improve resource use. They automate tasks like irrigation control or seed placement precisely. This cuts water use and waste. It boosts crop yields.

Energy-saving designs lower fuel use in hydraulic-powered machines. As farming shifts to renewable energy, like solar-powered gear, efficient hydraulics matter more.

Durable materials extend the life of a small hydraulic cylinder. This reduces replacements and waste. Eco-friendly fluids ensure less environmental harm.

Shenzhen Yijing Technology Co., Ltd.’s custom solutions tackle sustainability issues in farming. They optimize gear performance.

Frequently Asked Questions

What is a small hydraulic cylinder used for?

It’s used in compact farm machines. Space is tight there. It delivers precise straight-line motion.

How often should I maintain hydraulic cylinders?

Care depends on use. Check monthly for leaks or damage. Service yearly for lubrication and cleaning.

Can damaged hydraulic cylinders be fixed?

Yes. Hydraulic cylinders repair can fix leaks or bent rods. It often avoids full replacement.

Are there green options for hydraulic systems?

Yes. Eco-friendly fluids and energy-saving designs exist. They support sustainable farming.

For solutions from firms like Shining Hydraulic in Yantai Economic Zone, contact us today!