Overview of Hydraulic Cylinder Applications in the Oil and Gas Sector

Hydraulic cylinders hold a key spot in the oil and gas field, where exactness, strength, and speed matter a lot. These parts are crucial to fluid power setups. They turn hydraulic energy into mechanical push. Their wide use makes them vital for tasks from drilling to keeping pipelines in shape.

The Role of Hydraulic Cylinders in Fluid Power Transmission

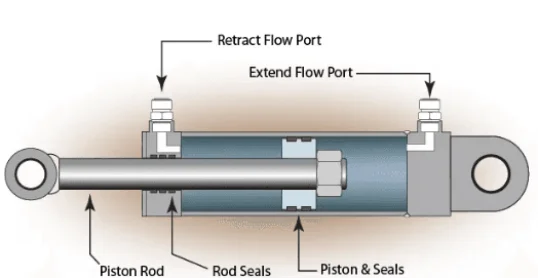

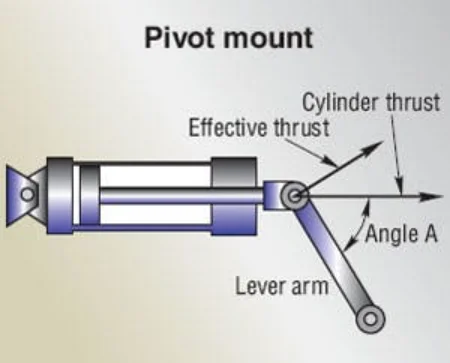

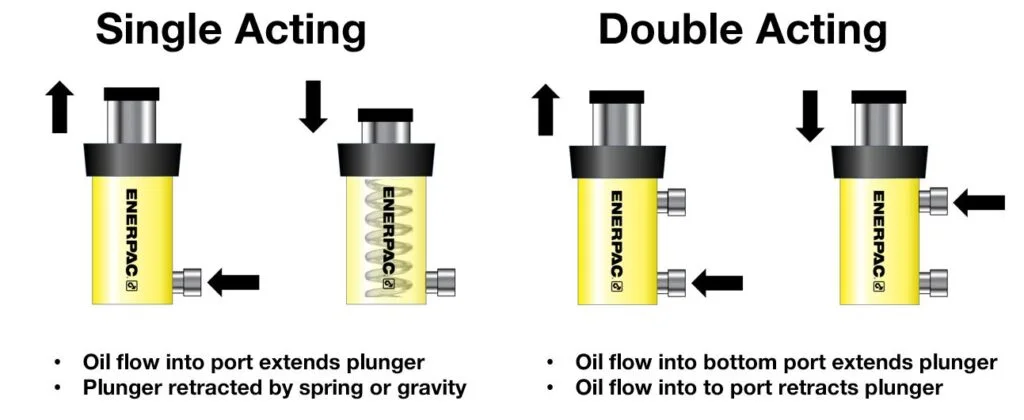

Hydraulic cylinders are the backbone of fluid power systems. They work by changing hydraulic pressure into straight-line motion and mechanical force. This skill is a must for tough jobs in the oil and gas world. Here, huge forces run gear like drill rigs and pipeline tools. By giving steady, managed motion, hydraulic cylinders keep tasks smooth and trustworthy.

Importance of Hydraulic Cylinder Selection for Efficiency

Picking the right hydraulic cylinder is critical to boost efficiency in oil and gas work. Things like load limit, stroke reach, pressure level, and build materials need close thought to fit the job’s needs. A good pick lifts performance. It also cuts downtime and upkeep costs. This keeps things running well in harsh settings.

Hydraulic Cylinders in Drilling Operations

Drilling tasks in the oil and gas trade call for precision, safety, and toughness. Hydraulic cylinders sit at the core of these efforts. They supply the force needed to punch through hard rock layers while keeping gear moves in check.

Application of Hydraulic Cylinders in Drill Rigs

Drill rigs lean hard on hydraulic cylinders for jobs like lifting and dropping drill strings, managing drill bit pressure, and steadying the rig frame. These cylinders are built to handle big pressures and rough conditions. That makes them perfect for deep-sea drilling or land-based searches.

Enhancing Precision and Safety with Hydraulic Cylinders

Adding advanced hydraulic cylinder designs sharpens precision in drilling work. Tools like position sensors and feedback setups let workers track cylinder action live. This gives tight control over drilling details. Such accuracy boosts work speed and ups safety by cutting risks of gear breakdowns or mishaps.

Common Challenges in Drilling and How Hydraulic Cylinders Address Them

Drilling often hits snags like gear wear, wild heat, and high-pressure zones. Hydraulic cylinders tackle these with sturdy builds using materials like high-strength steel. Advanced sealing tricks stop leaks under strain too. Plus, their steady force keeps things rolling even in tough spots.

The Function of Hydraulic Cylinders in Pipeline Operations

Pipeline tasks cover building, fixing, flow managing, and pressure tuning—all needing solid hydraulic setups. Hydraulic cylinders bring the power and exactness to handle these jobs well.

Controlling Flow and Pressure with Hydraulic Actuators

In pipeline networks, hydraulic actuators with cylinders play a big part in managing flow speeds and keeping pressure right. They tweak valve spots with care. This keeps pipelines running smoothly without overpressure or leak worries.

Applications in Pipeline Construction and Maintenance

During pipeline building, hydraulic cylinders help bend pipes into form or hoist heavy chunks into place. In upkeep jobs, they aid with things like swapping valves or fixing pipe lines. Their knack for controlled push makes them key to keeping pipelines strong through their whole life.

Enhancing Operational Efficiency Through Advanced Cylinder Designs

New hydraulic cylinder designs use perks like rust-proof coatings and energy-saving features to lift work speed. These updates cut power use while stretching gear life—a big deal for cost-smart pipeline handling.

Custom Solutions for Oil and Gas Equipment Manufacturers

Designing Tailored Hydraulic Cylinders for Industry Needs

The oil and gas trade works in some of the planet’s roughest spots. Gear here must stand up to wild heat, high pressures, and rust-heavy conditions. Hydraulic cylinders are no different. Crafting them to meet exact work demands is a must for top performance and long life.

Custom hydraulic cylinders get shaped to fit the oil and gas field’s unique calls. These made-to-order fixes weigh factors like load limit, stroke length, and setting challenges. Take offshore drill platforms: they need hydraulic cylinders with top-notch rust-proof coats to fight saltwater wear. Likewise, subsea cylinders must take on huge water pressure while keeping sharp control over moves.

Teaming up with skilled makers lets oil and gas firms ensure their hydraulic setups match their exact wants. This tailoring lifts work speed. It also trims upkeep costs by cutting wear on gear.

Benefits of Partnering with Specialized Manufacturers

Working with makers who focus on hydraulic cylinder design brings plenty of perks for oil and gas gear runners. These pros carry deep know-how, letting them craft fresh fixes for tricky issues.

Specialized makers often use the latest tech in their crafting steps. For example, advanced testing tools can check cylinder designs under all kinds of work conditions before they’re made. This ensures the end product hits or beats what’s expected.

Another plus is getting high-grade materials. Makers seasoned in oil and gas know how vital it is to pick stuff that holds up in rough spots. High-strength alloys, rust-proof coatings, and top sealing tech often get used to boost toughness and trust.

Plus, pairing with a focused maker gives more room for design tweaks. Be it resizing to fit a certain tool or adding bits like position sensors for live tracking, these custom touches can seriously lift system performance.

Future Trends in Hydraulic Cylinder Applications for Oil and Gas

Innovations in Material and Design Technologies

The future of hydraulic cylinder use in oil and gas is getting shaped by fast leaps in material know-how and design tricks. One hot trend is crafting light yet tough materials that trim gear weight without losing power or performance. These materials boost energy savings. They also ease hauling and setup—a key point for far-off or sea-based jobs.

Another fresh area is weaving smart tech into hydraulic cylinder builds. Sensors tucked inside can send live info on stuff like pressure, heat, and spot. This data backs predictive upkeep plans, letting workers fix issues before they spark big downtime costs.

Additive crafting, or 3D printing, is also leaving its mark on hydraulic cylinder making. This tech gives more design freedom by letting complex shapes happen that old crafting ways couldn’t touch. As a result, tailored fixes can roll out quicker and cheaper.

The Impact of Automation on Hydraulic Cylinder Performance

Automation is reshaping how hydraulic setups get built and run in oil and gas. Automated systems with sharp control math can tune hydraulic cylinder performance. They tweak things like force push or stroke pace based on live sensor feedback.

One big win from automation is sharper precision in tasks. Take automated drill rigs: they use hydraulic cylinders with tight control tools to keep drill bit pressure just right all the time. This lifts speed and cuts wear on parts.

Automation also boosts safety by cutting human steps in risky zones. Remote-run or fully self-working setups with hydraulic actuators can handle jobs like pipeline checks or valve tweaks. This skips risks tied to high-pressure spots or harmful stuff.

As automation grows, we’ll likely see tighter links between hydraulic setups and digital tools like artificial intelligence (AI) and machine learning (ML). These leaps could overhaul how hydraulic cylinders get used across oil and gas tasks.

Frequently Asked Questions (FAQs)

What is a hydraulic cylinder application?

It means using these tools to turn fluid power into mechanical push for trade tasks like drilling or pipeline work.

Why are customized hydraulic cylinders important?

Tailored fixes ensure they meet exact work needs, boosting speed while trimming upkeep costs.

How do advanced materials improve hydraulic cylinder performance?

Stuff like high-strength alloys gives toughness in harsh spots. Light options lift energy savings without losing power.

What role does automation play in modern hydraulic systems?

It sharpens precision with live tweaks from sensor data and ups safety with remote running skills.

For more info on how Shining Hydraulics drives new ideas in crafting custom fixes for trades like oil & gas gear making—reach out today!