Why is Routine Inspection Essential to Hydraulic Cylinder Life?

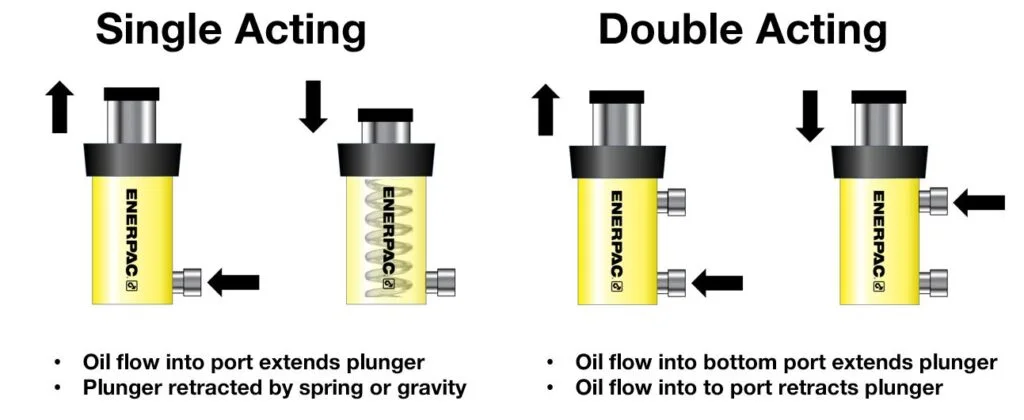

Routine inspection is needed in double-acting welded hydraulic cylinders maintenance since it is economically favorable in cost and repair time. Routine inspection will detect the initial sign of wear and tear and will provide the opportunity to carry out early maintenance, maximizing the life of the hydraulic system.

What Do You Inspect?

1. Cylinder Rod Condition

Inspect rod surface for corrosion, pitting, or scratches. Damage will result in seal wear and fluid leaks.

Straighten rod—a bent rod will result in misalignment, uneven wear, and failure.

Polish off small scratches using fine emery cloth, and replace rod for severe damage.

2. Seals and Gaskets

Inspect for cracking, deterioration, or wear that will result in hydraulic fluid leaks.

Even slight seepage of seal point area needs to be replaced immediately.

3. Cylinder Barrel Integrity·

Inspect externally for corrosion, cracking, or denting that impacts performance.

Where accessible, inspect internally for scoring or wear.

Shield externally from corrosion with coatings.

4. Mounting Hardware and Connections·

Inspect bolts, nuts, and brackets for looseness or wear to maintain alignment.

Inspect hydraulic hoses for cracking, leakage, or abrasion that result in fluid loss.

Tighten fittings securely and use proper sealants to prevent leaks.·

How Often Should Hydraulic Cylinders Be Inspected?

Heavy-duty use: Every week or every fortnight.

Moderate use: Monthly.

Light-duty use: Annually.

Keep first-class records of inspections to track cylinder conditions year to year.

Why is Lubrication at the Heart of Hydraulic Cylinder Operation?

Lubrication is required to reduce friction, wear, and free hydraulic cylinder motion. It simplifies the motion of moving parts and adds life.

How Does Lubrication Benefit Hydraulic Systems?

1. Avoids Friction and Wear

Avoids wear and friction by way of free motion of moving elements.

Lubrication avoids friction in moving parts like pistons and barrels, wear and their life is also avoided.

2. Heat Disipation

Allows disipation of heat generated while the system operates, thereby avoiding overheating and damage to parts.

3. Prevention of Corrosion and Contamination Deposition

Creates a water and dust-proof film covering which prevents corrosion possibilities.

Avoids leakage by maintaining seals in elastic condition.

What are the most effective lubrication methods?

Apply intermittent thin film of petroleum- or silicone-type lubricant on cylinder rod.

- Check hydraulic fluid levels frequently to obtain proper lubrication.

- Apply filtering system to filter out dirt from hydraulic fluid to keep system in operation longer.

- Check hydraulic system operation—high friction or unusual noise could be lubrication issues.

How does choosing the right hydraulic fluid influence Cylinder efficiency?

The proper hydraulic fluid prevents seals from swelling, hardening, or degrading. Viscosity and fluid properties within normal range make it easy to operate a system.

What Do You Need To Take into Account While Choosing Hydraulic Fluid?·

Viscosity: More lubricating but hard to pump fluids are thicker.

- Manufacturer’s suggestion: Consult the manufacturer of the cylinder for the fluid.

- Resistance against anticorrosive: Use anti-wear additive and corrosion inhibitor fluids to increase longevity.

- Environmental conditions: Use dust wipers and seals protection in dirty or wet environments to prevent contamination.

How to Monitor and Maintain Hydraulic Fluid Quality?

Why is Fluid Quality Important?

The hydraulic fluid is the lifeblood of the system, lubricates, disspates heat, and wears away. Quality monitoring at regular time intervals prevents failure and repair work at high cost.

How to Check Hydraulic Fluid Quality?·

Draw periodic fluid samples from return lines, reservoir, and pump.

Test metal shavings, soil, test air, and water—every spot system leakage or wear is illustrated here.

Perform an additive concentration and viscosity test in an attempt to obtain high lubrication levels.

Use filter units and dehydrators when filtering impurities and water.

Hydraulic fluid is stored in the required working temperature ranges not to generate oxidation as well as degradation.

Why Leak Detection is Most Important to System Operation

What Leaks Can Create as Troublesome Issues are Engaged

Pressure loss, reducing overall system efficiency.

- Environmental hazard due to fluid spillage.

- Lubrication deficit due to component failure.

How to Detect and Prevent Leaks?·

Visual check of fluid indication on hoses, fittings, and cylinders.

- Pressure testing for detecting leaks by detecting pressure loss.

- Use UV-reactive leak dyes to detect concealed leaks.

- Replace worn seals, hoses, and gaskets at regular intervals.

- Keep record of frequent occurrence for leak incidents documentation.

How Proper Cylinder Alignment Impacts Cylinder Efficiency?

Why Cylinder Alignment

Misalignment will lead to excessive wear, poor performance, and premature failure. Proper alignment will help have no excessive hydraulic component stress.

How to have Right Cylinder Alignment?

Surfaces which should be levelled and clean to mount.

Cylinder centerline should be on movement line.

Mount spherical bearings to have flexible mounting points.

Use shims to correct fine misalignments.

What are the Precautions Against Corrosion?

How can Cylinders be protected against corrosion?

Use protective coatings or stainless-steel components.

Keep the cylinders in clean, dry locations when not in use.

Use rust preventers where there is water or moisture exposure.

Why Shining Hydraulics for Your Hydraulic Cylinder Needs?

Who is Shining Hydraulics?

Shining Hydraulics is a veteran hydraulic cylinder manufacturer providing solutions to the construction industry, agricultural, mining sectors, etc.

What makes Shining Hydraulics unique?

20+ years of industry experience.

State-of-the-art R&D and innovative manufacturing processes.

Stringent quality control at every stage.

Custom-made hydraulic products to order.

Why Choose Shining Hydraulics?

Quality control with care for long-lasting, durable products.

Economical and efficient production.

Efficient logistics chain for timely delivery.

Conclusion: How Do You Maximize Hydraulic Cylinder Life?

Maintenance, lubrication, top-grade hydraulic fluid, and leak protection are the keys to high-performance and long-life hydraulic cylinders. Count on experience, quality components, and improved service with Shining Hydraulics to meet all your hydraulic requirements.