Forklifts have become quite indispensable, finding applications from logistical facilities down to heavy industries in manufacturing. The hydraulic cylinder is simply an important core component that helps in lifting, tilting, and maneuvering of weighty loads. Thus, the correct installation and servicing of hydraulic cylinders in a forklift are quite important in optimizing their service, making them safe to operate, and assuring a very long lifetime of service.

Why Proper Installation Matters

Hydraulic cylinders work in a forklift solely on proper installation. Improperly installed cylinders have a bundle of problems associated with them, including hydraulic fluid leakage, reduced efficiency, uneven load distribution, and even catastrophic failure of equipment. According to a report by the International Fluid Power Society (IFPS) in 2021, about 40% of hydraulic system failures are due to incorrect installation or bad maintenance practices. This again underlines the importance of adherence to industry standards and manufacturer recommendations. Installation of hydraulic cylinders also has some legal implications.

Pre-Installation

Make sure, before installing the hydraulic cylinder, it has been inspected and approved according to the model requirements. Proper preparation will help in reducing chances of errors and system failure.Shining Hydraulics has made the process quite simple with custom-designed hydraulic cylinders, fitted for certain applications like hydraulic cylinders for port forklifts, telescopic models that are precision-engineered, keeping high pressure and heavy-duty loads in mind.

In that respect, reliability for installation can be ensured with quality hydraulic cylinders. Shining Hydraulics may serve that purpose by possessing strengths in such materials as 25Mn in their manufacture and heat treatments that would help them bear extremely high pressure in application, a condition which again will reduce destruction upon assembling. Such factors actually reduce time and cost in the longer perspective.

Installation Steps

Below are essential steps one would consider in installing hydraulic cylinders for forklifts.

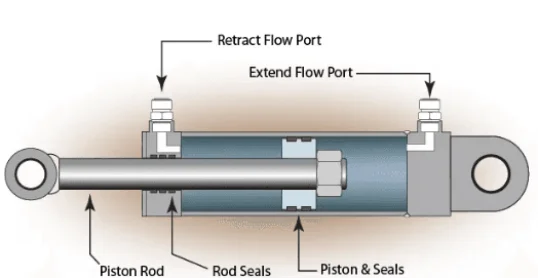

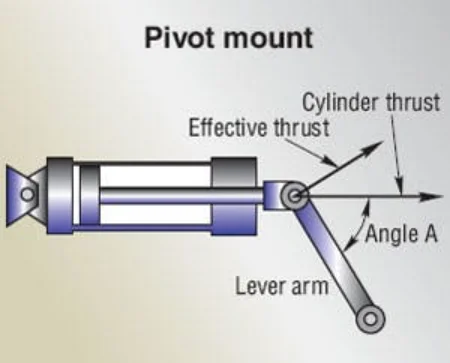

- Align the Cylinder Properly:Proper alignment between the cylinder and the forklift mounting points will prevent uneven wear or stresses on the cylinder. Misalignment is one of the causes of seal failure and operational inefficiency in the hydraulic system. According to theHydraulic Institute, most hydraulic component wear is due to alignment errors.

- Mounting Connections with Security:The hydraulic cylinders need to be well-mounted to the forklift structure. Hydraulics supplied by Shining Hydraulics are fitted with forged connections that raise durability and strength when its installation is carried out. These kinds of connections bear high-level vibration and load to make long-lasting stability effects.

- Contamination Check:Even a small amount of contamination or little dirt in the hydraulic system may be the cause of hydraulic fluid contamination, hence internal destruction. Shining Hydraulics uses imported seals like Hallite and DLI. These provide very high resistance against such contaminants and increase service life for cylinders.

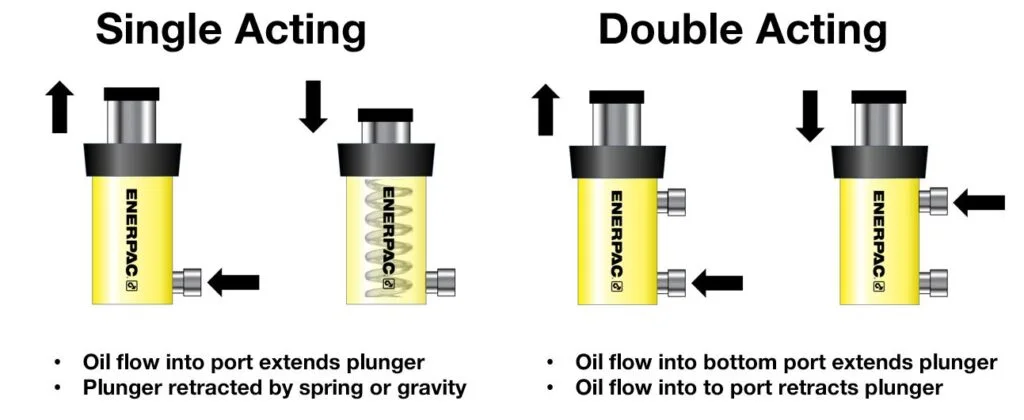

4.Pressure Test: The hydraulic pressure test should be conducted after installation and should indicate if the system operates within a set pressure. Hydraulics’ cylinders at Shining are made for high-pressure conditions and hence suitable for use in forklifts where operations are quite demanding.

Optimizing Performance of Cylinders in Use

Correct use is crucial after the installation of hydraulic cylinders in securing a long life of performance. A forklift operator can utilize these best practices in an effort to be more efficient:

Avoid Overload: Every hydraulic cylinder can bear only an amount of load. Overloading gives rise to strained or damaged conditions within the system. Hydraulics’ forklift cylinders are fabricated from high-strength cold-drawn materials and durable piston rods that have been tested under extreme conditions to give reliable performance at maximum load conditions.

Operate Within the Recommended Temperature Range: Hydraulic systems are sensitive to temperature extremes. For instance, hydraulic fluid, in most cases, undergoes thermal shock outside of operating range, hence becoming less effective. The normal operating temperature for Shining Hydraulics-made cylinders ranges from -25°C up to +120°C, though customization options may be made upon request for even more extreme conditions.

Hydraulic Fluid Quality Monitoring: Poor hydraulic fluid quality or an internally damaged cylinder can contaminate or deteriorate hydraulic fluid. Shinning Hydraulics applies advanced technologies in sealing with very minimal fluid contamination, increasing the intervals of services.

Look for Wear and Tear: This also includes regular wear marks or leakages, minor scratches on the piston rod at the seal area and elsewhere in the structure. The superior electroplating with salt spray testing done on Shining Hydraulics piston rods increases the power of their wear and corrosion resistance. Hence, this type of damage hardly ever happens.

Best Maintenance Practices

Proper maintenance means longevity in performance for hydraulic cylinders on forklifts. Professionals in the industry do recommend scheduled maintenance programs that minimize downtime while extending the life of components. In fact, according to the results of a2020 Fluid Power Journal survey, companies employing preventative maintenance programs reduced hydraulic system failures by 30%.

Shining Hydraulics supports this effort of maintenance by designing the cylinders with features that will support easy upkeep. Their hydraulic cylinders feature professional cushion designs for minimum impact, which reduces wear during operations. Further still, it also contains an imported sealing system with quality materials to overcome harsh environments for reduced frequencies of repair.

Why Choose Shining Hydraulics for Forklift Hydraulic Cylinders?

Shining Hydraulics, located in the Yantai Economic and Technological Development Zone of the Shandong Free Trade Zone, is a name trusted for hydraulic cylinder manufacturing. The company, though established in 2021, boasts more than 30 years of experience in this industry. Their hydraulic cylinders for forklifts epitomize the company’s commitment to quality, durability, and innovation.

Shining Hydraulics’ forklift hydraulic cylinders boast:

Compact, space-saving designs that allow their structure to maximize space without sacrificing the strength and durability of the unit.

Robust construction: The use of high-strength materials, such as 25Mn steel and advanced treatments, further guarantees superior performances under heavy loads.

Improved corrosion protection: The piston rod surface is electroplated with Ni/Cr and processed with rigorous salt spray tests for resistance against harsh environmental conditions.

Reliable Sealing Technology: High-quality seals imported against leakage assure low maintenance cost and consequent performance consistency.

Customization Options: The customers’ operational specifications about temperature ranges and the selected materials can be applied to the configuration of the cylinders. Working with Shining Hydraulics, it is true business in finding a partner who can offer more than just direct factory pricing and fast delivery but who will support a customer from design through after-sales.

Conclusion

Innovation, quality, and customer satisfaction have been at the heart of Shining Hydraulics’ business, hence always remaining a reliable partner in offering dependable forklift hydraulic cylinders to businesses. Shining Hydraulics offers advanced engineering combined with custom features that can meet the particular demands of an industrial application and still meet international standards.