Hydraulic cylinders are an essential element to most industrial processes, and with them in tow, mobile heavy equipment and machinery get the job done. Hydraulic cylinders suck in the pressurized hydraulic fluid and convert it into linear motion that drives a gigantic array of processes in the construction, mining, agricultural, etc. industries. In order for hydraulic cylinders to function at their maximum, one must know what its most important part is and how all these parts fit into it so that it will function at its maximum.

What is the most important part of a Hydraulic Cylinder?

What is Cylinder Barrel used for?

The cylinder barrel is the structural core of a hydraulic cylinder. It is a tough steel tube, machined for survival against high internal pressure, and as housing for a piston. Inner barrel surface is machined to provide good surface so the piston slides well without wear to the internal seal. Steel cylinder barrel is used most but for a particular application aluminum or composite is used. The barrel is made to a specific measurement in order to allow it to be made in such a manner that it can accommodate various hydraulic systems so that it can provide specifications required on the machine where it has been fitted.

How Does the Piston Assist Cylinder to Operate?

What Is the Primary Function of the Piston?

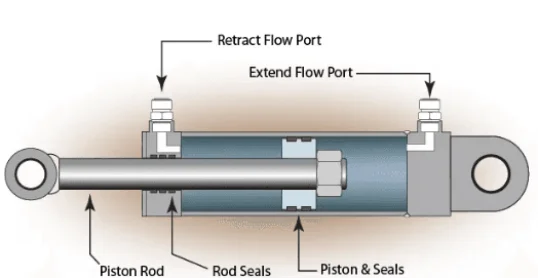

Piston is a circular disc-shaped member which is fitted within the barrel cylinder and which is used in the conversion of hydraulic pressure to linear motion. Hydraulic pressurized liquid entering the cylinder forces the piston against the cylinder, and the piston responds by moving. Piston movement when in extension or retraction mode is transmitted to the mounted piston rod, thus propelling the mounted machinery or device.

How Cylinder Head and Cap is associated with Cylinder Sealing System?

What is the use of Cylinder Head?

A portion of the other half of the cylinder barrel is occupied by a cylinder head (gland), a sealing piece to trap pressurized fluid. Ports on the cylinder head for the input and output of hydraulic fluid are provided for the hydraulic fluid.”. One of the easiest uses of the cylinder head is to provide a seal around the piston rod as close to possible so that there will be no leakage of the fluid sensed when the piston moves. The cylinder head is usually made of metal, and it is sealed by the use of rubber, polyurethane, or anything else.

How Does the Cylinder Cap Work?

The cap performs the same sealing function on the opposite side of the cylinder, trying to maintain pressure within and leakage without. Head and cap are easy to remove to be repaired and serviced. They seal the cylinder when operating, but they also protect against dust and dirt entering the internal hardware.

Why Seals and Rings Are Such an Important Component of Hydraulic Cylinders

What are the Types of Seals Hydraulic Cylinders Use?

Seals and rings are the major components that prevent hydraulic fluid leakage and thus the system is maintained in the intended pressure. O-rings, piston seals, and rod seals are the form of seals which can be used in hydraulic cylinders. They are manufactured from rubber, plastics, or metal based on the fluids employed, pressure, and temperature. They should be monitored on a routine basis since a compromised or over-tightened seal will develop leakage, pressure drop, and system contamination.

How Do Seals and Rings Maintain Cylinder Performance

The primary function of seals and rings is to seal pressure inside the hydraulic cylinder to be employed in generating force. They become a reason for failure and inefficiency induced by the system through the leakage of hydraulic fluid. Seals need to be correctly chosen with respect to the application requirement, and maintenance needs to be done correctly so that they could perform at their best.

What Are Base Ends and Rod Ends, and How Do They Impact Cylinder Performance

How Rod Ends Work

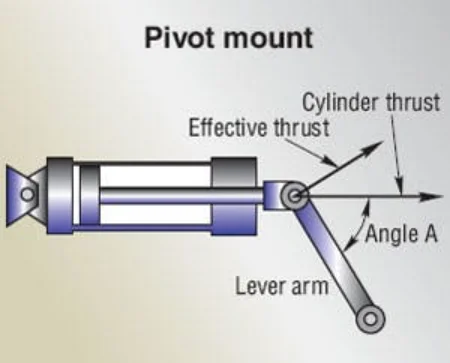

Rod end is a location where piston rod extends in the cylinder. Rod end is used to connect piston rod with outside gear or accessories operated by hydraulic cylinder. Rod end can be of various types such as threads, flanges, or clevis mounts depending upon application.

What is Base End

The base end is where the hydraulic cylinder is properly fastened in supporting service. The cylinder is mounted and held in machinery at the base end securely. Rod and base ends ought to be properly shaped and properly aligned in such a manner that no more stress is transmitted to the cylinder, causing failure or high wear and tear.

What Takes Place Within the Cylinder While It’s Operating?

How Do Different Cylinders Operate?

The piston rod has to be made of tough and durable material so that it is not eroded by rigorous operating conditions and mechanical stresses. There are different seals involved in the cylinder head in the seal gland filled with hydraulic fluid that helps in keeping the system away from dust.

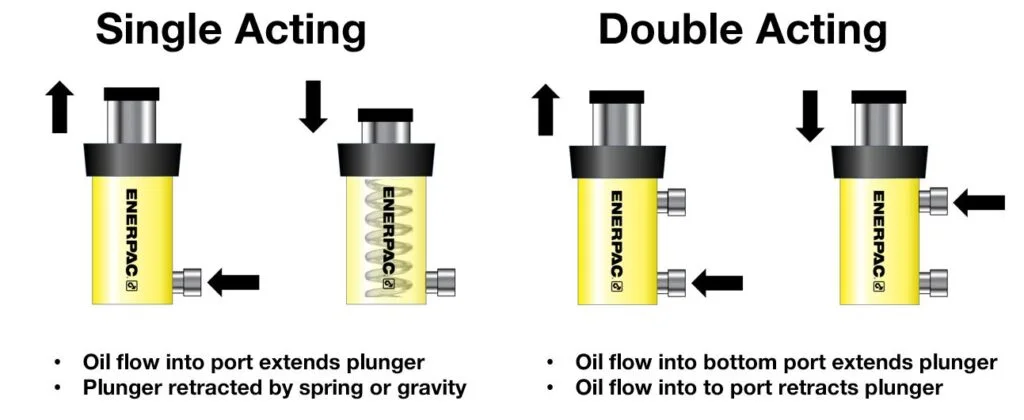

Pressure is one-way only in single-acting cylinders and spring return or external pressure piston to home position. Tie-rod cylinders, for low-duty operations, consist of outside rods with end caps and allow for easy maintenance and repair.

How Can Shining Hydraulics Improve Hydraulic Cylinder Performance?

What Services Does Shining Hydraulics Provide?

Shining Hydraulics is a designing and manufacturing firm that produces hydraulic cylinders to be used in various industrial processes like construction, agriculture, mining, and motor automobile. Shining Hydraulics has existed for more than 20 years, and they produce high-performance cylinders to provide efficiency, reliability, and longevity. Shining Hydraulics has technical personnel who are made up of experts, and they select the appropriate cylinder depending on functionality, size, and application need.

What Type of Hydraulic Cylinders Does Shining Hydraulics Provide?

What Type of Hydraulic Cylinders Are They?

Shining Hydraulics manufactures hydraulic cylinders of various types for various industrial applications. Some of them are:

- Construction equipment

- Agricultural equipment

- Miners

- Rubber machines

- Automobile maintenance

- Environmental protection and sanitation service

- Aerial working devices

Shining Hydraulics also provides hydraulic stations and systems apart from hydraulic cylinders.

How Does Shining Hydraulics Provide As Per Your Requirements?

Shining Hydraulics‘ R&D division and their quality manufacturing process supply all hydraulic cylinders of international standards. The company’s strict quality check and test process makes every product reliable and worth the money. Shining Hydraulics’ customer-centric business and their seamless logistic partners ensure your hydraulic solutions to be delivered on time and to highest quality standards.