Hydraulic systems are the backbone in modern forklifts, which have to raise and lower with such great heavy loads at a very great tilt.

In this blog, we go in for a deep dive into the importance of the right hydraulic cylinder choice for forklifts, factors that influence the same, and types of hydraulic cylinders used for different forklift applications. We will further be discussing the expertise of Shining Hydraulics in manufacturing quality hydraulic cylinders for forklifts and their commitment to customer satisfaction.

The Critical Role of Hydraulic Cylinders in Forklift Performance

Forklifts cannot be replaced in the motion of goods through warehouses, building sites, and many other industrial applications. They use hydraulic systems for lifting pallets, tilting the mast, and steering the vehicle. Hydraulic cylinders are central to these systems, converting hydraulic fluid pressure into useful mechanical force to achieve these functions.

The hydraulic cylinder plays the following major roles in forklift operations:

Hydraulic cylinders control upward and downward motion; hence the ability of raising and lowering of a load with the mast of a fork-lifter.

Tilting: It aids fork-lifters to alter the mast’s angles properly.

Steering control: It involves hydraulic cylinders in service primarily within power-steered lift trucks that could maintain running smoothly by providing minimal exertions from the operators.

These functionalities make hydraulic cylinders a direct influence on the efficiency, safety, and maintenance costs of forklift operations.

Key Factors to Consider When Choosing Hydraulic Cylinders for Forklifts

The selection of the right hydraulic cylinder for your forklift is based on a series of technical specifications and conditions of operation. Some major factors affecting such a choice will include:

1. Load Capacity and Stroke Length

First, the hydraulic cylinder has to be rated for load-carrying capability, since a forklift is designed for certain weights; similarly, the hydraulic cylinder also must be able to bear such loads safely and efficiently. Stroke length refers to the distance traveled by a cylinder’s piston. This comes into play with the height of the forklift when it goes to lift a load.

The Forklift Manufacturers’ Association – FMA claims that forklift capacities will generally fall anywhere between 3,000 pounds and 15,000 pounds, but certainly, there is the possibility for heavy-duty models with capacities above this general range; the cylinders of such a high-capacity forklift-one used on a construction site, perhaps-would call for much heavier load ratings when combined with longer strokes.

2. Operating Pressure

Pressures are different in hydraulic systems and generally range from 2,000 psi to 3,000 psi. For reasons of efficiency and safety, one has to select such hydraulic cylinders that will bear the forklift system’s maximum operating pressure. According to ISO 10100: Hydraulic Fluid Power – General Rules for the Design and Construction of Hydraulic Cylinders, the cylinders should be rated to high-pressure applications to make them long-lasting and reduce any possibility of failure.

3. Cylinder Material and Coatings

Material and coatings are the most important in the hydraulic cylinder to bear such operational cycles of a cylinder, especially when forklifts have to operate under harsh conditions. Common materials for hydraulic cylinders are carbon steel and stainless steel, which are good in strength and resistant to wear.

Where conditions tend to be more moist, or to rust or corrosive materials, cylinders should have corrosion-resistant coatings, such as chrome plating or Ni/Cr coatings. According to Hydraulic and Pneumatic Systems Magazine, proper selection of a coating will ensure that the hydraulic cylinder behaves accordingly, even in harsh environments, outdoors, and in marine applications.

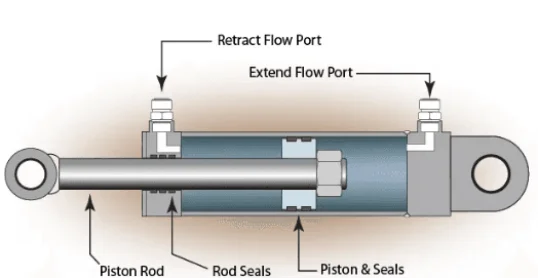

4. Seals and Maintenance Requirements

Seals prevent hydraulic fluid from leaking out and keep pressure inside the cylinder; they also prevent contamination. Type of seal used in service life determination of hydraulic cylinders and ways to minimize operating expenses: For example, double-acting seals prove to be a lot more durable in extremely dusty or dirty environment conditions. In fact, Hydraulic Institute Standards explain that when seals are made from superior quality material, such as NOK seals, the incidences of failures related to the seals will reduce and, therefore enhance general system efficiency.

5. Temperature and Environmental Conditions

The working range of forklifts lies within a very extreme range of temperatures-from high heat to below-freezing cold. Hydraulic cylinders will have to do their job efficiently under those extreme conditions. Operating Temperature for hydraulic cylinders: -25°C to + 120°C though in harsher conditions specific solutions can also be made available.

For instance, in the case of a cold storage forklift, low-temperature seals on cylinders will be required so as to avoid such seals becoming brittle under freezing temperatures, while for industrial use under high ambient temperature, a cylinder should be able to hold its performance in hot conditions.

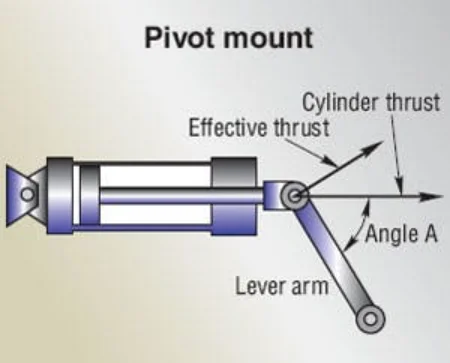

6. Mounting Configuration

Hydraulic cylinders have a number of mounts, the proper selection of which guarantees that the cylinder can be accommodated by a forklift design easily. Some of the mounting styles adopted for hydraulic cylinders in forklifts are flange mounts, trunnion mounts, and clevis mounts. Appropriate mount types ensure proper alignment, consequently offering minimum friction, enhancing the operating lives of cylinders as well as the forklift.

Types of Hydraulic Cylinders Used in Forklifts

Forklift hydraulic cylinders are available in various sizes and shapes, all meant to carry out specific tasks. Some common types are highlighted below.

1. Lifting Cylinders

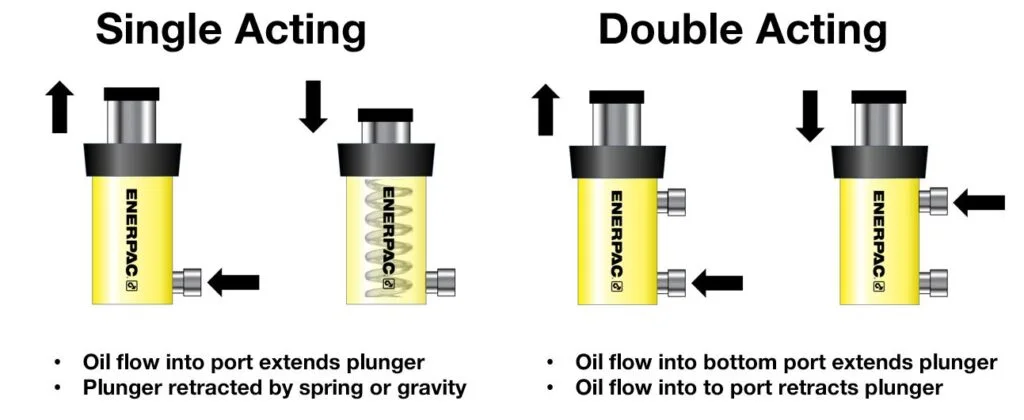

The purpose of a lifting cylinder is to raise or lower the forklift mast; they have to be designed in a manner to support the loads they would carry. Such cylinders would very well often be double acting-that is, go up and come down using a force applied to them.

2. Tilt Cylinders

Tilt Cylinders: These enable the tilt of the mast, allowing the forklift operator to change the angle of the load. These are usually single-acting cylinders providing force in only one direction, that is, the forward or backward tilting.

3. Steering Cylinders

Steering cylinders help control the wheel movements of the forklift. Power-steering forklifts use hydraulic cylinders for steering, hence their accuracy during operation. These cylinders are normally single-acting and work under lower pressure compared to the lifting or tilt cylinders.

Industry Standards and Regulations relating to Hydraulic Cylinders on Forklifts

Shining Hydraulics, located in Yantai, China, designs and manufactures high-quality hydraulic cylinders for many applications, including forklift systems. Since 2021, Shining Hydraulics has been applying over 30 years of industry experience to manufacture reliable, efficient, and customized hydraulic products.

Why Choose Shining Hydraulics for Your Forklift Hydraulic Cylinders?

- Customized and Expertise:Shining Hydraulics offers hydraulic cylinders in customized conceptions aimed at solving the specific needs of the forklift application. A highly qualified R&D team with extended manufacturing experience in hydraulic products provides solutions just right for your needs.

- High-Quality Materials and Advanced Manufacturing: Shining Hydraulics applies high-strength materials with specialized heat treatment processes in making forklift cylinders durable. They also offer corrosion-resistant coatings and advanced sealing technologies for enhanced reliability in the most challenging environments.

- Strict Quality Control:Every hydraulic cylinder is tested under rigid conditions to ensure conformation to international standards. Shining Hydraulics warrants its products to be free of defects and to increase the operating effectiveness of your lifts while reducing maintenance costs.

- Competitive Price and Fast Delivery: Due to lean manufacturing processes, Shining Hydraulics is able to offer very competitive pricing while the performance and reliability levels of these remain high. Fast response times with effective delivery just prove that they do care for the needs of their customers.

Shining Hydraulics Commitment to Customer Satisfaction

Shining Hydraulics pays much attention to forklifts’ effective and efficient operation. The company is committed to rendering the best hydraulic solution to satisfy all your needs. From custom-made hydraulic cylinders to excellent customer service and enhanced engineering, Shining Hydraulics is distinguished from other strategic business partners in every industry.

Conclusion

The selection of the right hydraulic cylinder for a forklift application is very important in terms of safe, efficient, and cost-effective operations. Informed decisions based on load capacity, pressure ratings, material quality, seal configurations, and environmental conditions will enhance performance in forklift systems and extend service life.

For businesses requiring high-quality, reliable hydraulic cylinders, Shining Hydraulics offers customized solutions with decades of experience and advanced manufacturing capabilities. Contact Shining Hydraulics today to learn more about how their forklift hydraulic cylinders can improve your operations.

It points out all the important factors that are to be considered in hydraulic cylinder selection for forklifts and positions Shining Hydraulics as the world expert in the provision of custom hydraulic solutions for manifold applications, such as systems of forklifts.