Overview of Hydraulic Cylinders in Aerospace

Hydraulic cylinders are key pieces in the aerospace world. They play a vital role in keeping aircraft systems safe, swift, and working well. These tools turn fluid power into mechanical push. This makes them essential for many tasks in aviation.

Fundamental Role of Hydraulic Cylinders in Aircraft Systems

Aircraft setups depend a lot on hydraulic cylinders for their work. These cylinders help manage flight parts like ailerons, rudders, and elevators. They ensure steady moves and balance in the air by giving the push needed to tweak these crucial bits. Plus, hydraulic cylinders get used in landing gear setups. They make deploying and pulling back gear smooth.

Beyond flight controls and landing gear, hydraulic cylinders also work in cargo doors, thrust reversers, and brake systems. Their wide use lets them shine in tough conditions like high skies and changing heat. This keeps performance steady across an aircraft’s run.

Key Advantages of Using Hydraulic Cylinders in Aerospace

The aerospace field needs parts that can handle harsh demands while staying top-notch. Hydraulic cylinders bring several perks that fit this trade well:

- High Power Density:They pack a big power-to-weight punch. This is key for keeping aircraft light yet efficient.

- Precision Control:These tools allow tight movement management. That’s a must for running flight surfaces right.

- Durability:Built to last in rough settings, hydraulic cylinders use materials that fight wear and rust.

- Reliability:Their tough build ensures steady work even under wild pressures and heat.

- Compact Design:Hydraulic setups can fit in tight spots without losing their edge.

Hydraulic Cylinder Application in Aircraft Maintenance Equipment

Beyond their job in aircraft setups, hydraulic cylinders see wide use in ground support gear. This gear backs planes during checks, fixes, and big repairs. Such use keeps safety high in these tasks.

Use of Hydraulic Cylinders in Maintenance Equipment

Use of Hydraulic Cylinders in Airframe Tripod Jacks

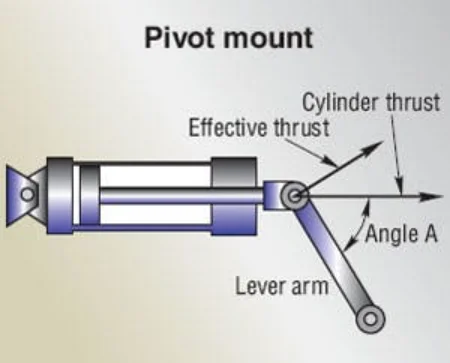

Airframe tripod jacks are must-have tools for lifting and steadying planes during upkeep. Hydraulic cylinders act as the heart of these jacks. They supply the lift needed to hoist heavy airframes off the ground. The exactness from hydraulic systems keeps the plane level during fix-up jobs.

These jacks need to manage big weights while staying firm. Hydraulic tech lets workers lift planes with ease and less hand work. Also, the flexibility of hydraulic cylinders suits them to different plane types by handling varied load needs.

Stabilizing Stands Powered by Hydraulic Cylinders

Stabilizing stands are key for keeping plane parts still during fix or tweak jobs. Powered by hydraulic cylinders, these stands give adjustable support shaped for spots like wings or engines.

Adding hydraulic tech to stabilizing stands boosts their ease and bendability. Workers can shift the height or tilt of support frames fast with little strain. This comes from the smooth running hydraulic systems offer.

Importance of Hydraulic Cylinders in Aircraft Hoists

Aircraft hoists with hydraulic cylinders are vital for lifting big parts like engines or landing gear during swaps or fixes. The sharpness and strength these systems bring make them great for managing tricky yet hefty pieces without harm.

Hydraulic-powered hoists ensure careful moves when lifting or dropping gear. This cuts risks tied to hand-handling slips. Their steady push also lifts safety levels in upkeep hubs.

Role of Hydraulic Cylinders in Flight Control Systems

How Hydraulic Cylinders Enable Precise Wing and Flap Adjustments

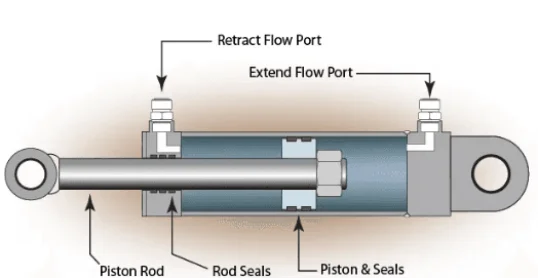

Hydraulic cylinders are crucial for fine-tuning wings and flaps on planes. These parts turn hydraulic fluid power into mechanical push. This allows smooth, managed shifts of wings and flaps. Such exactness is a big deal. Even small tweaks to these surfaces can greatly sway a plane’s airflow and steadiness in flight.

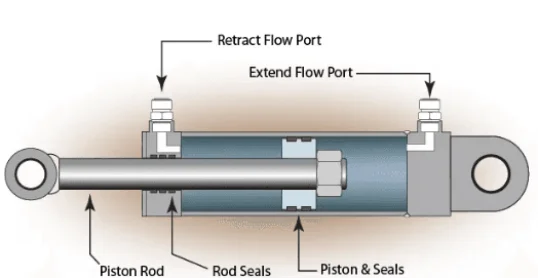

With hydraulic cylinders, pilots can adjust the attack angle or lift from wings on the fly. This skill matters for top performance in takeoff, cruising, and landing phases. The strong power density of hydraulic setups ensures these shifts happen fast, boosting quick response.

Hydraulic cylinders also ease pilot strain by handling tricky moves on their own. Say, in rough air or fast height shifts, the system can tweak wing spots quick to keep balance and safety. Adding smart sensors lifts this further. They give feedback for live tweaks.

Application in Rudder and Elevator Control Mechanisms

Beyond wings and flaps, hydraulic cylinders get heavy use in managing rudders and elevators too. These bits handle a plane’s yaw (side sway) and pitch (up-down tilt). By pushing out exact mechanical force, hydraulic cylinders keep these control surfaces running smooth.

The trustworthiness of hydraulic setups shines in rudder controls. During crosswind landings or sharp turns, the rudder needs to act fast to pilot cues to hold direction steady. Hydraulic cylinders bring the push to pull this off while taking big air loads.

Elevator controls gain from hydraulic tech too. Shifting the elevator’s spot directly sways a plane’s climb or drop speed. Hydraulic cylinders make these shifts with high sharpness. This ensures smooth hops between flight heights.

The toughness of hydraulic systems lets them work steady in wild conditions like high skies or quick heat changes. This lasting strength is key for keeping safety and performance up through a plane’s life.

Future Trends in Aerospace-Grade Hydraulic Cylinders

Advancements in Lightweight Materials for Aerospace Applications

As aerospace pushes for fuel savings and green goals, there’s a growing focus on light materials for hydraulic cylinders. Old-school stuff like steel is giving way to advanced mixes and high-strength alloys. These offer the same toughness at less weight.

These steps cut a plane’s total heft and boost its load room and range. Lightweight hydraulic cylinders help hit these targets without skimping on performance or safety.

Plus, new crafting ways like additive manufacturing (3D printing) are shaping cylinder builds. This lets complex shapes form with less waste. It also trims costs while opening doors for more custom fits.

Innovations in High-Pressure Hydraulic Systems for Enhanced Performance

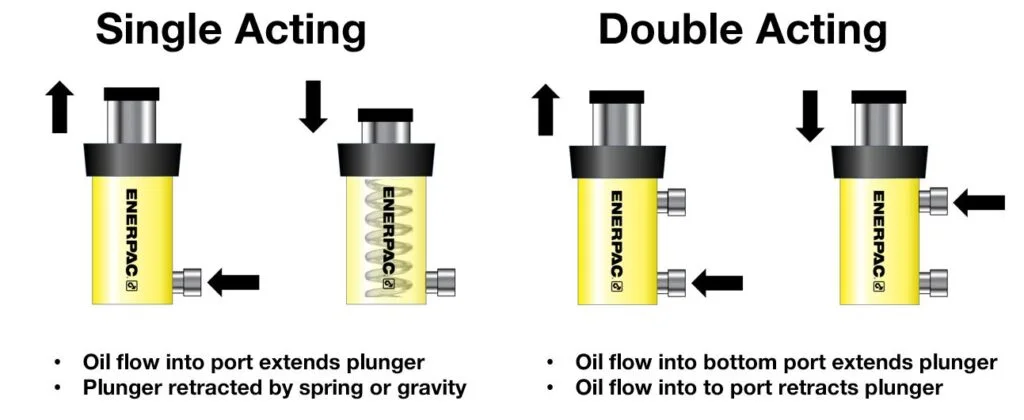

Another big shift shaping aerospace-grade hydraulic cylinders is high-pressure systems built for better output. Running at higher pressures, these setups push out more force with smaller parts. This leads to tighter, sharper designs.

High-pressure hydraulic systems also save energy by cutting fluid leaks in use. This perk helps trim upkeep needs and stretch part life—a win for planes.

Weaving smart tech into hydraulic setups is shaking things up too. Sensors inside cylinders can track live stats like pressure, heat, and wear signs. This info backs plans to fix issues before they cost big downtime.

Frequently Asked Questions (FAQs)

How do hydraulic cylinders contribute to flight control?

They allow fine tweaks to key surfaces like wings, flaps, rudders, and elevators for top airflow.

What materials are used in modern aerospace-grade hydraulic cylinders?

Advanced mixes and high-strength alloys get used a lot for their light build and toughness.

Why are high-pressure hydraulic systems important?

They push more force with smaller bits while saving energy and cutting upkeep needs.

Can aerospace hydraulic cylinder applications be customized?

Yes, makers like Shining Hydraulics craft custom fixes shaped for unique aerospace hurdles.

For more on how Shining Hydraulics leads in crafting sharp solutions across fields like aerospace, feel free to reach out!