Getting to Know Single-Acting Hydraulic Cylinders

What They Are and How They Work

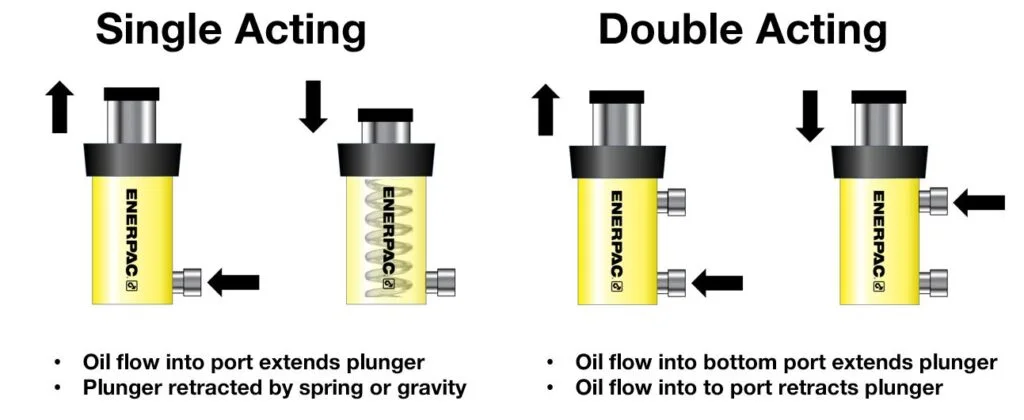

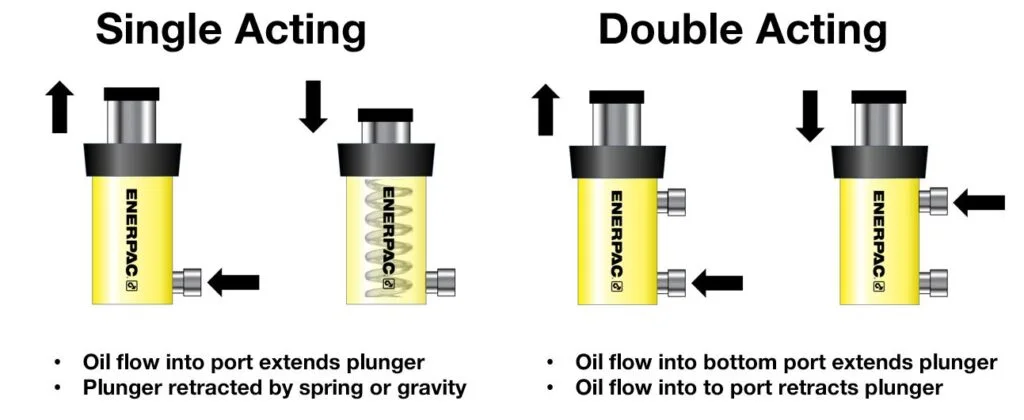

Single-acting hydraulic cylinders are a type of tool that moves stuff in a straight line. They use hydraulic fluid under pressure to get the job done. These cylinders push or pull in just one direction. That’s their main gig. Here’s how they roll: hydraulic pressure hits one side of the piston inside the cylinder. This shove moves the piston and creates force. To get back to where it started, it needs help from something outside—like a spring or gravity. That’s what makes them different from other cylinders.

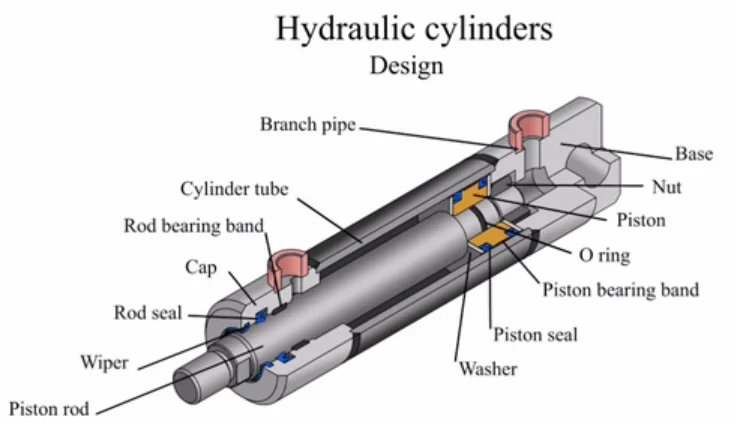

Parts That Make Them Tick

Single-acting hydraulic cylinders have a few key pieces:

- Cylinder Barrel: The main shell. It holds the piston and keeps the fluid inside.

- Piston: A moving part that splits the cylinder in two. It turns fluid power into push or pull.

- Rod: Tied to the piston. It passes the force out to whatever needs moving.

- Seals: These keep the fluid from sneaking out. They also lock in the pressure.

- Spring (sometimes): In some setups, a spring kicks the piston back to start after it’s done.

All these bits team up to keep things running smooth, tough, and trusty for all kinds of jobs.

How They Stack Up Against Double-Acting Cylinders

Single-acting cylinders aren’t like their double-acting cousins. Here’s the deal: single-acting ones use fluid pressure to move one way. Something else—like gravity—brings them back. Double-acting cylinders, though, use fluid to go both ways—out and back. That makes them handier for some tasks. But it also means they’re trickier to build than single-acting ones.

What’s Cool About Single-Acting Hydraulic Cylinders

Easy Design and Build

These cylinders keep it simple. They’re not hard to put together. That cuts down on costs to make them. Plus, looking after them isn’t a big hassle compared to fancier setups. With fewer pieces to wear out, they tend to last longer too.

Why They’re a Win

- Cheap to Get: Their basic setup keeps the price low compared to other types.

- Simple Fixes: Fewer parts mean repairs are quick and easy.

- Small Size: They squeeze into tight spots. Perfect when space is tight.

- Saves Power: They don’t guzzle energy. They move one way and let outside help handle the return.

These perks make them a solid choice for jobs needing straight-line action.

Where They Fall Short

They’ve got some downsides though:

- One-Way Only: They’re stuck doing tasks that need force in just one direction.

- Need Outside Help: Springs or gravity have to pull them back. That doesn’t always work out.

- Not Super Strong: They can’t lift as much as double-acting cylinders.

These quirks mean you’ve got to pick the right tool for the job.

Where You’ll Find Single-Acting Hydraulic Cylinders

Farming Gear

In farming, these cylinders show up in stuff like plows, harvesters, and loaders. They give steady, straight motion. That keeps things humming no matter the weather or dirt.

Construction Machines

Think dump trucks or excavators. Single-acting cylinders lift or tilt stuff there. They’re tough enough to handle big loads day after day.

Car Lifts

In car shops, these cylinders power lifts and jacks. They’re small but mighty—lifting cars without breaking a sweat.

Trash Trucks and Green Machines

Garbage trucks use them to squash waste. Their no-fuss design fits right in with rough, messy work.

Picking the Right Single-Acting Hydraulic Cylinder

Figuring Out Bore Size and Stroke Length

Choosing one means nailing down bore size and stroke length. Bore size sets how much push the cylinder can muster. It’s about the area the fluid presses on. Bigger bore, bigger force. Match it to what you’re moving. Stroke length is how far the piston travels. It decides your motion range. Need to go far? Get a longer stroke.

Get these numbers right, or you’ll either overwork it or come up short. Check the specs and your needs to dodge mistakes.

Why Rod Size and Strength Matter

The rod’s a big deal too. It’s got to take the pressure without bending. How strong it is depends on its thickness, what it’s made of, and how long it stretches out. A skinny or long rod might buckle under load.

For heavy stuff or long reaches, pick a rod that’s up to it. That keeps things safe and lasting. Extra supports can help it stay steady too.

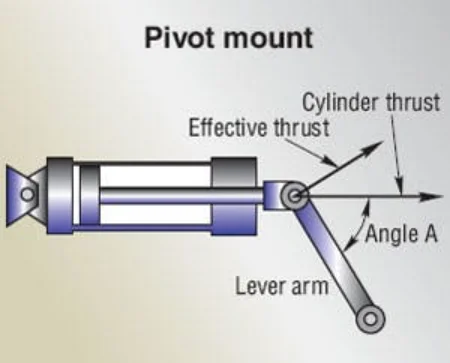

Choosing a Mounting Style

How you attach it matters. Options like flange, clevis, trunnion, or threaded mounts each have their vibe:

- Flange Mounts: Best for fixed spots needing perfect lineup.

- Clevis Mounts: Good when things need to swing a bit.

- Trunnion Mounts: Let it spin around one point.

- Threaded Mounts: Fit in tiny spaces.

The right mount keeps it working well. It also cuts wear from bad fits.

Keeping Single-Acting Hydraulic Cylinders Going

Top Tips for Care

Looking after them keeps them alive longer. Here’s what to do:

- Check Often: Look for wear, rust, or dents on the outside and seals.

- Fluid Check: Keep the hydraulic fluid full and clean. Dirty stuff messes things up inside.

- Swap Seals: Worn seals leak. Replace them fast to hold pressure.

- Grease It: Rub some lube on moving bits. That keeps friction low.

Stick to this, and they’ll run smooth. It cuts surprise breakdowns too.

Spotting Trouble and Fixing It

Even tough ones hit snags sometimes:

- Leaks: Worn seals or banged-up parts usually cause this. New seals fix it.

- Weak Push: Low pressure or leaks inside might be why. Check fluid and the system.

- Rust: Wet or rough spots can eat at it. Paint or cleaning helps.

Jump on these quick to keep things rolling. It stops bigger headaches.

Keeping Them in Top Shape

Good care isn’t just checks. Watch the surroundings too:

- Keep them out of crazy hot or cold spots. That can wreck the materials.

- Don’t push them past their limit. Overloading wears them out fast.

- Stash extras somewhere dry and clean. Keep rust away.

This keeps them humming, even in rough jobs.

Frequently Asked Questions

What should I think about when picking a single-acting hydraulic cylinder?

Look at bore size, stroke length, rod size, strength, and mount type. They’ve got to match your job.

How do I look after one?

Check it regular, keep fluid clean, swap bad seals, and grease it up. That keeps it going strong.

What goes wrong with them?

Leaks from old seals, weak force from low pressure or leaks, and rust from tough conditions pop up.

How do I pick a mount?

Think lineup (flange), swinging (clevis), spinning (trunnion), or tight fits (threaded).

For custom fixes from Shining Hydraulics—pros at hydraulic gear for all kinds of work—hit us up today!